Mining Process Equipment

strategic partnership agreements,China's mining sector,industry Leaders

q,qa,a,sd,asdf

strategic partnershi

China's mining secto

mining industry,tech

internationalization

China Mineral Proces

future development,C

Nanchang Mining Mach

technological innova

China Metallurgical

Air Purification,Ind

High-efficiency exha

Industrial Waste Gas

activated carbon ads

Diesel Wet Concrete Sprayer HUPS-20JT

HUPS-20JT diesel engine wet concrete spraying vehicle is a new product developed by our company to adapt to the current mine underground construction technology. HUPS-20JT diesel engine wet concrete spraying vehicle adopts heavy articulated engineering chassis design, with reasonable structural layout and flexible mobility. At the same time, the whole machine is equipped with 45KW air compressor, which makes the construction process easier and more efficient.

Model: HUPS-20JT

Maximum spraying distance: 7.1m

Max spray height: 9m

Maximum spraying width: 14.8m

Engine power: 81kW

Product details:

Diesel Mix Wet Concrete Sprayer HUPS-20JT

Introduction of Diesel Wet Concrete Sprayer HUPS-20JT

HUPS-20JT diesel wet concrete spraying vehicle is a new product developed by our company to adapt to the current mine underground construction technology. It absorbs the advantages of famous brand products at home and abroad in design and manufacturing, and the main performance parameters far exceed the average level of domestic products of the same type.

Features of HUPS-20JT Diesel Wet Concrete Sprayer

▶Mechanical Boom

Longer service life, more stable and reliable performance, wide operation range, hydraulic control, sensitive operation and more convenient maintenance.

▶Electric Control System

HUPS-20JT is equipped with electric control system which makes the failure rate is very low and can adapt to the harsh environment. The panel adopts the sunken design to prevent misoperation.

▶Concrete Delivery Pipe

Large diameter pipeline is adopted for the transmission pipe to reduce the wear of concrete on the pipeline, prolong the service life of the pipeline, and have strong anti blocking ability.

▶Emergency System

When the power grid is powered off, the emergency system can be started, and the chassis engine can be used as the power to carry out all functions of emergency operation.

▶Air Compressor

Equipped with 45KW high-power air compressor, the disadvantages of limited equipment conditions under previous working conditions are solved, so that the equipment can be easily used in high-altitude areas and poor areas of on-site equipment under working conditions.

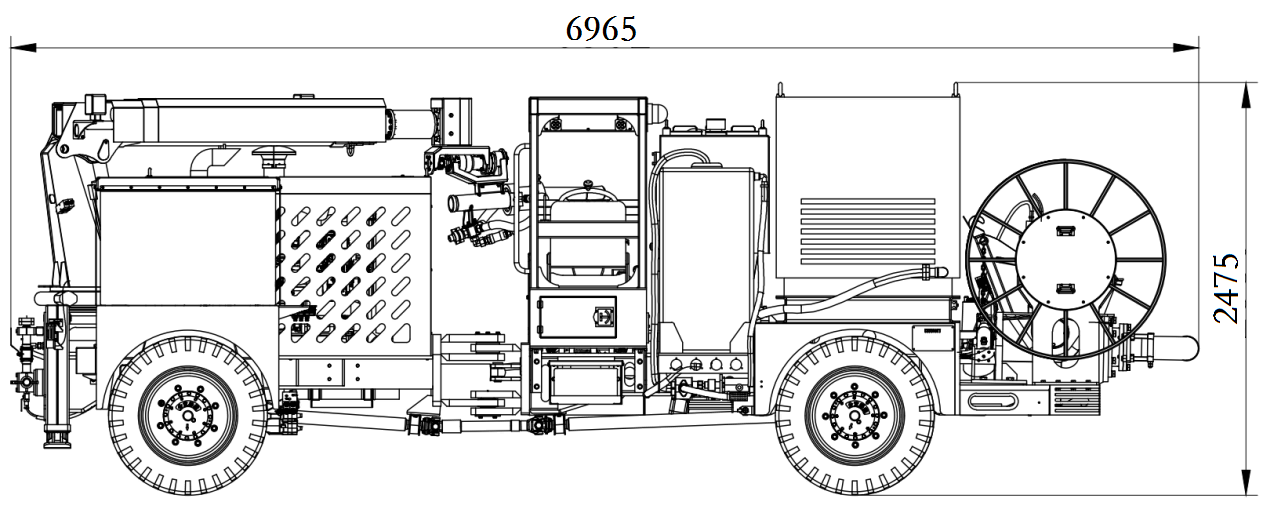

Specification of HUPS-20JT Diesel Wet Concrete Sprayer

|

Scope |

Subject |

Unit |

Parameter |

|

Overall unit specs |

Vehicle size(L*W*H) |

mm |

7000×2140×2450 |

|

Machine weight |

ton |

11 |

|

|

Articulation angle |

° |

±47.5 |

|

|

Pumping system |

Theoretical spray volume |

m3/h |

20 |

|

Diam of concrete cylinder |

mm |

ø140 |

|

|

Concrete cylinder stroke |

mm |

1000 |

|

|

Max particle size of sprayed aggregate |

mm |

ø15 |

|

|

Maximum pressure of pumped concrete |

bar |

60 |

|

|

hopper capacity |

m3 |

0.3 |

|

|

Walking system |

Traveling/steering mode |

|

Tyre travel/articulated steering |

|

Driving axle type |

|

Wet hydraulic drive axle |

|

|

Minimum turning radius |

mm |

3500/5500 |

|

|

Engine power |

kW |

81 |

|

|

Wheelbase*Track width |

mm |

4000*1540 |

|

|

Maximum traveling speed |

km/h |

18 |

|

|

Maximum gradient |

° |

16 |

|

|

Minimum ground clearance |

mm |

280 |

|

|

Braking distance |

m |

≤3.5 |

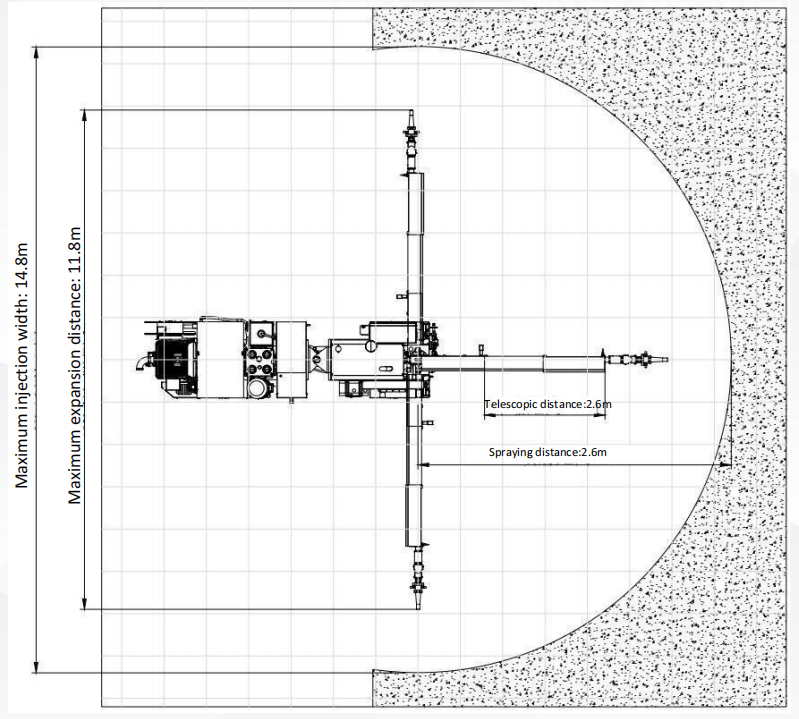

4.Spraying trajectory

Horizontal spray trajectory

The mechanical boom can rotate 270 ° in the horizontal direction (as shown in the right figure). It adopts a three-section two-stage telescopic structure, and the maximum diameter of spraying is about 14.8m.

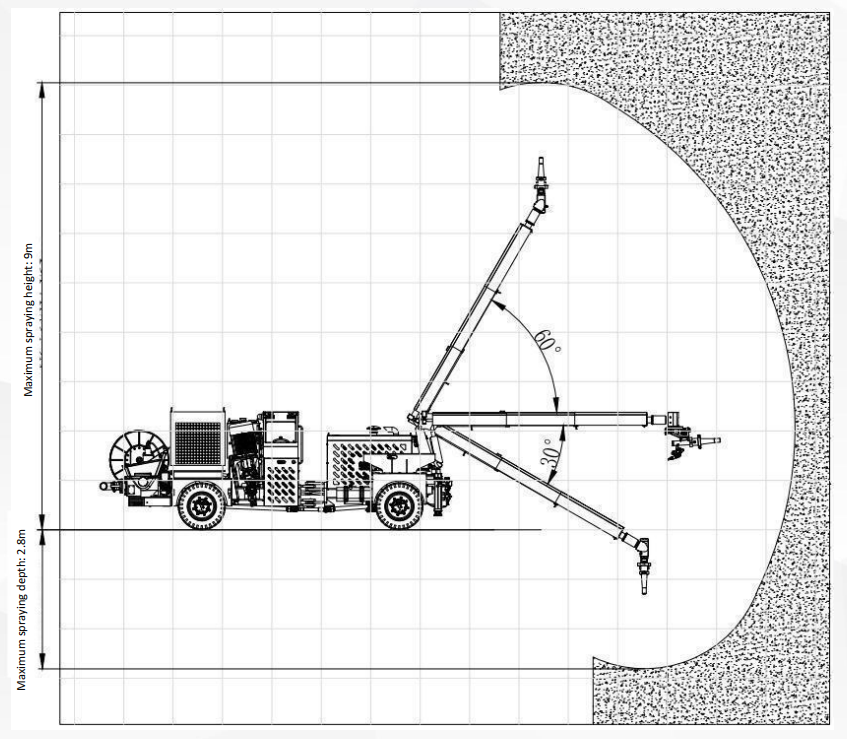

Vertical spraying trajectory

In the vertical direction of the mechanical boom, the boom can tilt up 60 ° and down 30 ° (as shown in the right figure). The maximum spraying height is 9m, and 2.8m can be sprayed downward.

5. Traveling state

Contact us:

William Lai

Email: william.lai@hot-mining.com

WhatsApp: +86 15756877473

Monica

Monica

Gary

Gary

Technician

Technician

Sarah

Sarah

Ben Zhao

Ben Zhao

ASTA(Dubai)

ASTA(Dubai)

Home

Home