Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

Coal Dry Preparation: ROM-JIG & XRT X-ray Transmission Sorter

Coal processing mainly has two aspects - water washing and dry processing. For water washing there’s process like jigging, DMC(dense medium cyclone) and flotation, the advantages are: mature process technology, big capacity; disadvantages are: heavy construction investment, high operation cost, and relatively heavy water consumption and waste. Dry processing is a kind of coal preparation method which has existed and been developed slowly for nearly 20 years. It has the advantage of no water, simple process, little investment and low operation cost. With the development of technology, ROM-JIG has inevitably become a out-dated coal processing equipment gradually. New type XRT intelligent coal dry processing has several advantages compared with past methods:

① Saving water.

Coal dry processing is a good method to solve this conflict, that's why it has been paid great attention by coal administration departments.

② Less construction investment.

By using coal dry processing method, we can develop coal preparation industry under conditions like little investment, low operation cost, less ground occupation and quick returns.

③ Solve the problem of water coal washing - easy-sliming.

Coal sliming increases coal preparation investment.

④ Avoiding freezing problem in alpine region.

⑤ Simplify the coal preparation process, no pollution to environment from coal slurry.

ROM-JIG has the disadvantages like high failure rate, poor stability, low separation precision, which leads to phenomenon like reject in coal and coal in reject. If there’s high content of coal in reject, the resources will be wasted, and loss of property; if there’s high content of reject in coal, the subsequent preparation process cost will be increased. In light of above, more advanced XRT intelligent dry processing method is called to replace traditional ROM-JIG.

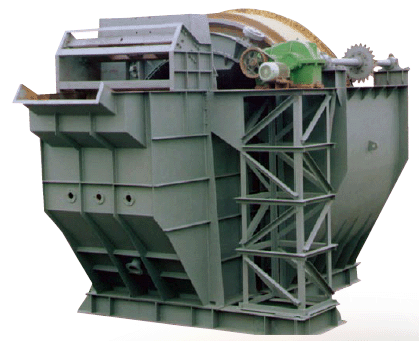

1. Design Principle of Mechanical ROM-JIG

2. Mechanical ROM-JIG Separation Effect Control and Main Parameter Adjustment

The advantage of mechanical ROM-JIG is easy to operate, it needn’t subsequent investment like medium and agent. The shortcoming is of course obvious, due to pick up running current of main drive motor to reflect screen main body’s loading condition, approximately reflect the thickness of waste rock bed layer, input source can not be selected precisely, and the separation is performed according to overall material layer, not individual, the output action is inaccurate. It usually results in poor separation effect, a majority of phenomenon like reject in coal and coal in reject, also it’s a waste of water (frequently changing water to avoid water too thick to influence the effect). The dereferencing of bed layer thickness test value is comparatively nebulous, the operator cannot adjust timely according to changing or feeding raw coal. The discharging process depends on overall bed layer, if the separation limit is obscure, the discharging cannot be controlled precisely, the whole separation process is nebulous.

3. XRT Intelligent Coal Dry Processing

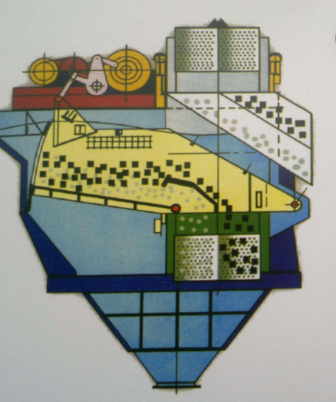

① Design Principle

XRT intelligent dry separator (X-ray Transmission Sorter) is researched and developed based on the principle of different absorption degree to X-ray from coal and waste rock. XRT intelligent dry separator can digitally identify coal and waste rock by using X-ray and image recognition technology, it can establish analytical model aimed at coal quality features and Big Data Analysis, afterwards next process will separate coal and waste rock.

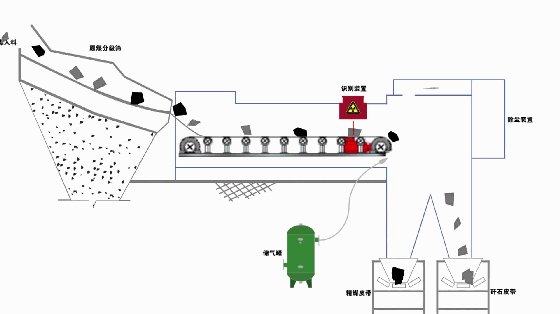

② Technological Process

Pave coal and waste rock on belt conveyor by using vibration feeder, scanning material’s cross section by X-ray emission instrument. Because of different absorption to X-ray from coal and waste rock, after the receiver receives X-ray, the distribution situation of coal and waste rock on belt conveyor can be known by analyzing X-ray’s reduction. The data is back-fed to control the on-off of air valve, air-blowing valves execute the blow to waste rock or coal, and then allocate different material into different chute inlets on the front end of belt conveyor.

XRT intelligent dry processing system includes four main sub-systems, feeding device, material distribution device, identification device and execution device, and three auxiliary systems, air supplying device, de-dusting device and electronic device. The above mentioned feeding device is located at feeding end of distribution device, raw material is fed onto distribution device uniformly; identification device is made up of X-ray source located above the distribution device and X-ray detector beneath the distribution device; execution device is an air jet nozzle whose outlet facing motion path of coal concentrate and waste rock; identification device can output position information to execution device besides identifying coal concentrate and waste rock by their physical property; air jet nozzles of execution device are arranged in array type, they can be motivated intelligently according to executed one’s position.

③ Brief Introduction of XRT Intelligent Dry Processing System’s Key Technology: Identification Tech

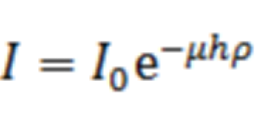

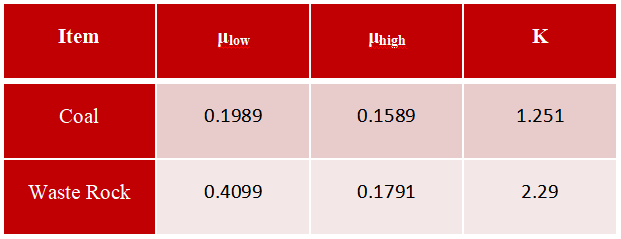

X-ray’s penetrability is related to object’s density. We can separate objects with different density by different frailty degree after X-ray passes through the object.

The identification principle is Lambert-Beer’s Law.

I&I0: X-ray intensity before and after passing through

μ: mass absorption coefficient

h: Identified object’s thickness

ρ: Identified object’s density

e: Natural constant, about 2.71828

Advantages of XRT Intelligent Dry Separator: accurate input source and output action because of different absorption on X-ray and respective separation action on each individual; no need water and following cost investment(agent and medium).

Disadvantages of XRT Intelligent Dry Separator: too much noise and dust; potential health hazard to plant operator if X-ray is not protected well. HOT Mining's newly developed model HXS Intelligent Dry Type Separator can solve the problems well!

④ Factors that Influences Separation Effect

- Material loose level. For XRT intelligent dry separator, the material is required to be arranged in loosely tiled way, no overlapping and snuggling. Misoperation greatly influences separation effect.

- To choose blow coal or waste rock. If the coal is blown, coal will be discharged out, misoperation part will go into waste rock discharging port, partial coal will be lost compared with blowing waste rock; if the waste rock is blown, only identified waste rock will be discharged out, there will be some waste rock in coal that is not identified timely.

- Accuracy of database analysis. The material usually displace on belt conveyor, and collision happens due to displacement, the relative position is changed, thus separation is influenced.

- Motion of blowing valves. The force is offset due to valves’ opening degree, some material which should be blown to distant chamber chute falls into nearby chamber due to force changes, thus causes the result of coal in waste rock and waste rock in coal.

Any more information about coal washing plant or centrifuge, can contact us:

Peter Gao, Intelligent Product Manager

Email: peter.gao@hot-mining.com

Tel/WA:+86 13436553365

Teresa Zheng, International Business Manager

Email: teresa.zheng@hot-mining.com

Tel/WA:+86 15281626323

Tari Wang, Mineral Process Engineer & Centrifuge Products Manager

Email: tari.wang@hot-mining.com

Tel/WA:+86 15927349651