Company:Chengdu Cobalt Mining Co., Ltd

Email: sales@hot-mining.com

Phone:+86 28 83311885

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

Case Study: A Gold Processing Plant Process Transformation and Upgrade

A gold processing plant in Song County, Henan Province adopts flotation + cyanide leaching + carbon slurry adsorption process. The final product is gold-loaded carbon, and cyanide tailings are directly discharged after pressure filtration. In actual production, the concentrating plant often has the phenomenon of process interruption and operation stoppage due to equipment failure, which greatly reduces the equipment operation rate and seriously affects the smoothness and continuity of the process. In addition, this gold processing plant has been in operation for a long time, the grade of feeding ore selected by the processing plant is decreasing year by year, and the ore is depleted seriously, the recovery rate of ore dressing is also reduced. Therefore, the process method has been modified to improve the equipment operation rate and the ore recovery rate, thereby improving the economic benefits of the enterprise.

1. Ore Property

1.1 type of ore

The type of ore in a gold mine is

altered coarse-faced rock. The main types of alteration are pyrolysis,

silicification, pyrite mineralization, chlorite petrochemical, local

silicification is strong, and quartz veins are visible. The ore is all native

ore. The ore process type is a small sulphide gold ore, and the metal mineral

is mainly pyrite.

1.2 Ore structure

Ore structure: anhedral form grain structure, inclusion structure, self-half self-shaped grain structure, polygranular structure, plaque structure, rough surface structure and so on. Most of the pyrite and natural gold, chalcopyrite, sphalerite, and galena are crystallized in the ore to form a anhedral form grain structure.

Ore structure: mainly disseminated structure, fine vein structure and so on.

1.3 Natural gold inlay state

The gold grade in the ore is

1.56g/t, mainly fine particles, and little micro-particles. Most of which are

concentrated in the range of 0.037-0.01mm. Natural gold is mainly embedded in

pyrite, mainly inclusion gold (89.64%), followed by cracked gold (10.36%).

2. Processing Plant Technological Process

2.1 Crushing

The raw ore from the primary

bin firstly enters the C80 type jaw crusher for coarse crushing, and

then enters the JP158 cone crusher for medium crushing. After the medium

crushing, it enters the 10mm*10mm vibrating screen. The ore larger than 10mm

returns to the JP108 cone crusher for fine crushing. Ore less than 10mm

directly enters the powder ore bin.

The ore directly enters the GQC2700*3600 grate ball mill (grinding medium is φ100mm cast steel ball) from the powder ore mine, and then enters the single spiral classifier. The coarse particles in the slurry become grit, and the fine particles are discharged from the overflow port. The finer particles passing through the classifier overflow into the hydro cyclone for re-classification. The overflow flows directly into the flotation process through the high-efficiency agitation tank, and the grit returns to the ball mill for re-grinding, thus forming a closed loop.

The flotation process is a closed circuit including once rough selection; three times fine selections, and twice sweep selections. The supplements are butyl xanthate and black no. 25, and the foaming agent is No. 2 oil. The flotation concentrate enters the thickener for concentration, and the flotation tailings are pumped into the tailings pond through a ball isolation pump.

2.3 Cyanide leaching and activated carbon adsorption

The flotation concentrate is

re-grinded by 3 mixing mills (grinding medium is φ10mm steel balls), so that

the fineness of the ore particles reaches -0.037mm, accounting for more than

90%, and then the slurry concentration is controlled to 37% by the mixing tank.

40%, and finally enter the charcoal dipping tank for leaching and adsorption to

obtain gold-loaded charcoal.

3.Upgrade and Modify the process

In actual production, improving equipment integrity and operation rate, maintaining production and process continuity and stability, can create favorable conditions for improving various technical indicators of mineral processing. In the process of mineral processing, promoting energy conservation and consumption reduction can effectively reduce energy costs and improve economic efficiency. As current production costs increase, metal loss should be reduced as much as possible. Therefore, reducing production costs and increasing the recovery rate of the processing plant has become important issues for it.

3.1 Modification of ball isolation pump

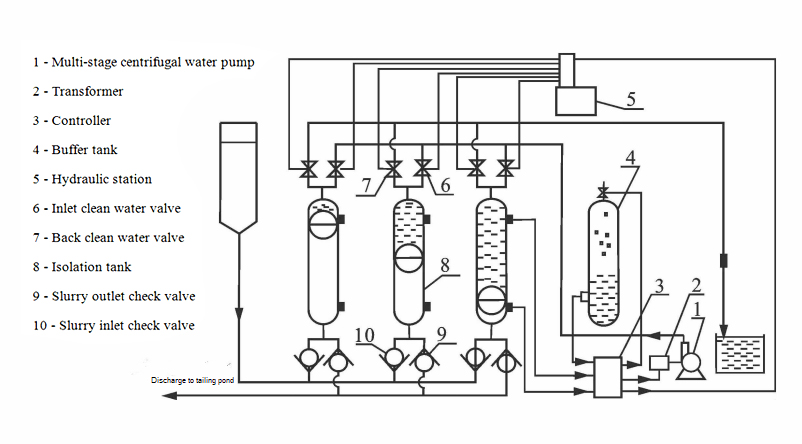

There are 2 ball isolation pumps in the processing plant, which correspond to 2 multi-stage centrifugal pumps, which can be used for 1 operation and 1 preparation. The multistage centrifugal water pump is connected to the ball isolation pump as shown in Figure 1.

Figure 1 Connection schematic diagram of multi-stage centrifugal water pump and ball isolation pump

In actual production, each device may malfunction at any time. This may cause No. 1 pump fail or No. 1 ball isolation pump fail. Then No. 2 pump and the No. 2 ball isolation pump must be used, if No. 2 pump or No. 2 ball isolation pump also failed, which inevitably caused the entire concentrating plant to be interrupted. In order to avoid such problems, the connection method between the pump and the ball isolation pump shall be improved: crosslink the inlet pipe of the No. 2 isolation pump, that is, the outlet pipe of the No. 2 pump, is cross-connected, which makes the No. 1 pump and 2 The ball isolation pump is connected, and the peer pump also connects the No. 2 pump to the No. 1 ball isolation pump, so that each pump or each ball isolation pump corresponds to the No. 2 ball isolation pump or the No. 2 pump. Therefore, when the No. 1 pump fails, it is only necessary to use the No. 2 pump, and it is not necessary to use the ball to isolate the pump. Other cases as well.

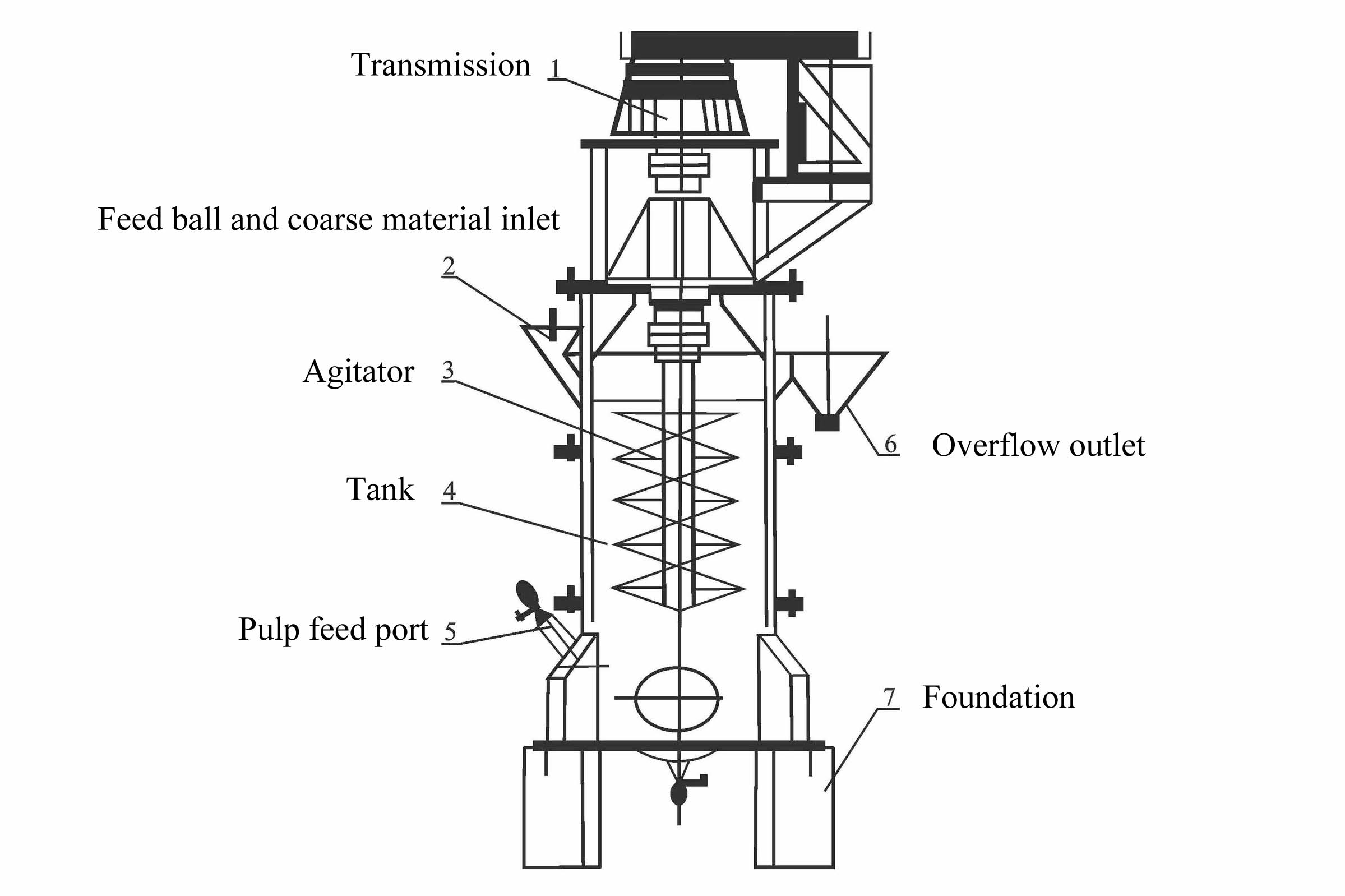

The re-grinding operation of the processing plant is carried out by three agitating mills. Although the fineness of grinding can meet the production requirements, from the perspective of energy saving and consumption reduction, the motor power of the agitating mill is 75kW, the power consumption is large, and the equipment is too old, and the work is not continuous. Therefore, it is replaced with a tower mill (motor power is 50kW), which not only can achieve continuous operation, but also consumes less than 1/3 of the agitating mill, which can greatly reduce the cost. The structure of the tower mill is shown in Figure 2.

Figure 2 Schematic diagram of

tower mill structure

The grinding fineness of the regrind operation can ensure good leaching effect at present, but in order to further improve the gold recovery rate, the barren liquid (mass concentration about 0.01 g/m3) after the activated carbon is adsorbed to the activated carbon is again sent to the activated carbon adsorption tower for further re-extraction. The adsorption (mass concentration after adsorption is 0.004 g/m3) can further increase the recovery rate by about 0.02%.

3.3 Cyanide tailing treatment

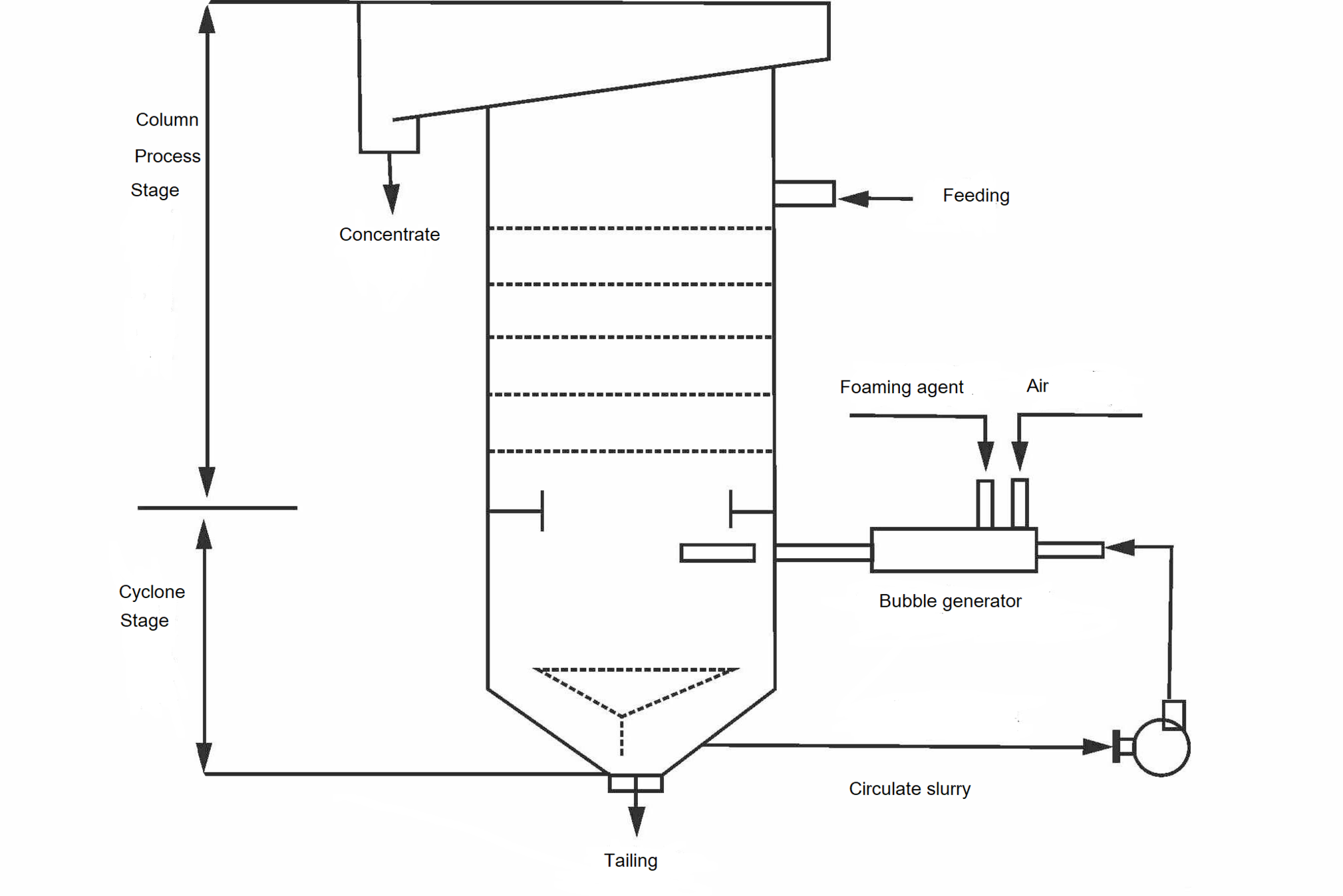

In the cyanidation tailing, due to the high grade of lead and other metals, the direct discharge after press filtering leads to the loss of metal. In the subsequent process, add a cyclone-static micro-bubble flotation column (see Figure 3). The slag is pumped into the flotation column for flotation, which can effectively recover metals such as lead.

Figure 3 Working principle of cyclone - static

micro-bubble flotation column

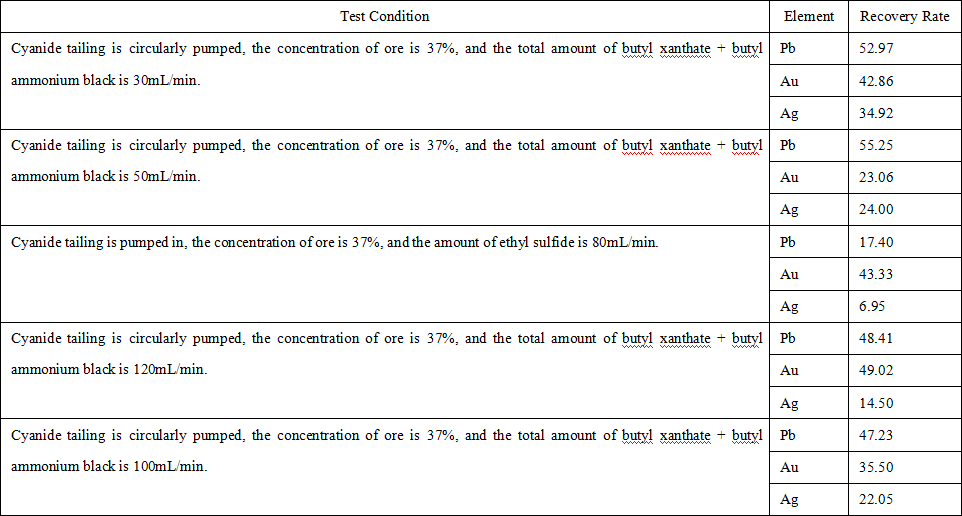

Different conditions were tested

on the new cyclone-static micro-bubble flotation column, and the flotation

condition of the flotation column was discussed. The total mass fraction of the

preparation was 20%. The test results are shown in Table 1.

Under different experimental conditions, through the comparison and comprehensive analysis of the recovery rates of gold, silver and lead metals, it can be seen that when the concentration density is about 37%, the dosage of butyl (butyl ketone + butyl ammonium black medicine) is 30mL, higher recovery rate can be obtained.

The processing capacity of the processing plant is 900t/d, and the output rate of cyanide tailing is about 3.8%, that is, the daily output of cyanide tailing is about 34.2t. The cyanide tailing gold grade is about 3.1g/t, the silver grade is about 34g/t, and the lead grade is about 3.5g/t. It can be estimated that the annual recovery of gold is 16.58kg, silver 48.19kg and lead 23.14kg. It can be seen that by increasing the flotation column, the re-recycling of gold, silver and lead can achieve certain economic benefits.

Table 1 Result of Conditional Test

4. Conclusion

In the actual production of the processing plant, failure of any one equipment may lead to interruption of the production process, so the high operating rate of the equipment is the guarantee of the stability and continuity of the production process. With the reduction of feeding ore grade and energy conservation and consumption reduction, it is urgent to reduce production costs and increase the recovery rate of ore dressing.

- 4.1 The modification of the ball isolation pump changed the previous "1 to 1" to "1 to 2", which avoids or reduces the stoppage of the production operation of the processing plant and improves the operation rate of the equipment.

- 4.2 The replacement of the agitating mill not only ensures the continuity of the process, but also saves electricity and achieves the purpose of energy saving.

- 4.3 The gold recovery rate can be improved by re-injecting the hydrogen-depleted lean liquid into the carbon adsorption column. The use of flotation column to re-recycle the metal in the cyanide tailing can greatly improve the process recovery rate, reduce metal loss, and obtain certain economic benefits.

With dozens of mineral processing

experts in the field of gold, copper, lead-zinc, silver, coal and etc., HOT Mining can

provide services for new mineral processing plant engineering

design(feasibility study, preliminary design, detail design and construction

design) and existing mineral processing plant modification and upgrade.

Especially we have rich experience in gold/copper CIP, CIL and flotation.

Contact us for more information:

| Serena | Kira | Teresa |

| serena.fu@hot-mining.com | kira.zhang@hot-mining.com |

teresa.zheng@hot-mining.com |

| Whatsapp: +86 15108333341 |

Whatsapp: +86 15281051932 |

Whatsapp: +86 15281626323 |

|

Skype: serena20140924 |

Skype:kira.zhangjing |

Skype:teresa.zheng123 |