Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

Coal Gangue Sorting System—HXS Intelligent Dry Type Separator

Traditional coal preparation methods include heavy media, jigging, and flotation. These methods have been applied in CHPP for a long history. All of them have a common feature is that high water consumption and needs disposal of sewage. While, the X-ray coal preparation method does not require water in the process of coal gangue separation, and has the advantages of low cost and no pollution.

What is HOT XRT Sorting(HXS)?

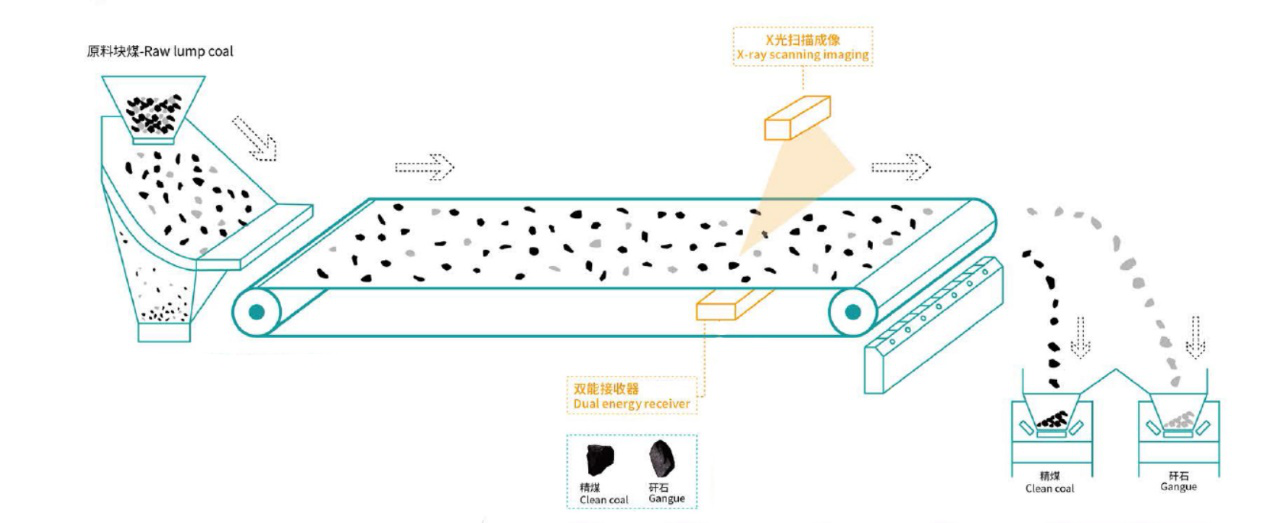

HXS Intelligent Dry Type Separator is a coal sorting equipment based on the advanced Imaging technology and AI technology. The coal and gangue are automatically analyzed and identified by X-ray imaging system, which can obtain the material characteristics, and control the high-pressure wind to blow the target materials away. Then the full-automatic raw coal separation is realized.

Structure of HXS

Based on X-ray and fiber optic sensor technology, it’s mainly composed of X-ray source module, detector module, fiber optic sensor module, pneumatic regulating valve sorting device, feeding device, conveying device and other structures. See the Figure 1 below:

Figure 1. The working system of X-ray sorting

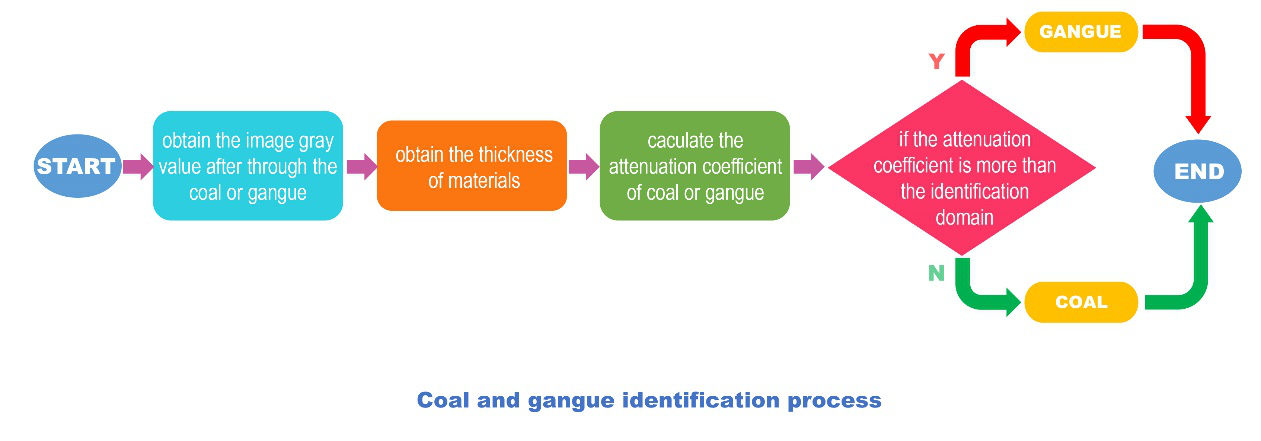

The system software mainly includes power control module, image gray detection module, thickness detection module and control module.

1. The power control module mainly realizes the start and stop of the X-ray source, the setting of voltage and current, and the control of the system power supply.

2. The image gray detection module processes the X-ray images of coal and vermiculite to obtain valid gray value information.

3. The thickness detection module mainly realizes the collection, storage and display of coal and vermiculite thickness information.

4. The main function of the control module is to ensure the coordination of the operation of the various parts of the system, to ensure the synchronization of the collected data, and to send sorting signals in a timely manner.

Figure 2. Coal gangue identification flowchart

Technical features

※ Wide processing size range: It can handle 30- 600mm raw coal. The upper limit of separation is 600mm and the lower limit is 30mm.

※ High separation accuracy: The rate of gangue removing is over 95%, the rate of coal in gangue is less than 2%, and the separation effect is significant.

※ Great processing capacity: The processing capacity is 140-320t/h for the mate-rials with different particle sizes.

※ High-level intelligence: Workers are not required to be on duty for a long time, and the fault can be self-detected.

Key Point of HXS system

X-ray intensity

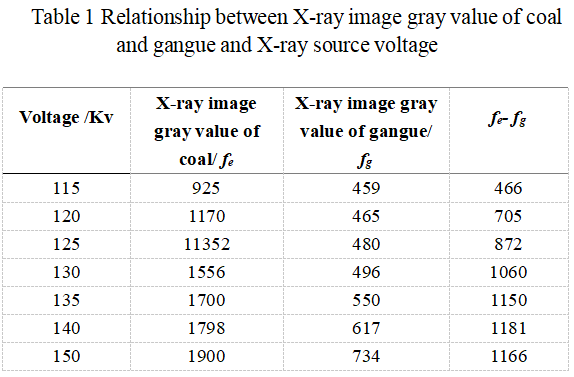

If the X-ray intensity is too small, it will not be able to penetrate coal or gangue. If the intensity is too large, it will cause a lot of radiation. Therefore, selecting the appropriate ray intensity is the key point of the X-ray dry separator.

From the experimental results in Table 1, it can be seen that as the voltage of the X-ray source decreases (ie, the intensity of the rays decreases), the gray values of the X-ray images of coal and gangue continue to decrease, and the difference of gray value increases first and then decreases. When the voltage is at 140Kv, the difference between the gray values of coal and gangue is the largest, which is easy for system to identify coal and gangue.

Thickness measurement of coal and gangue

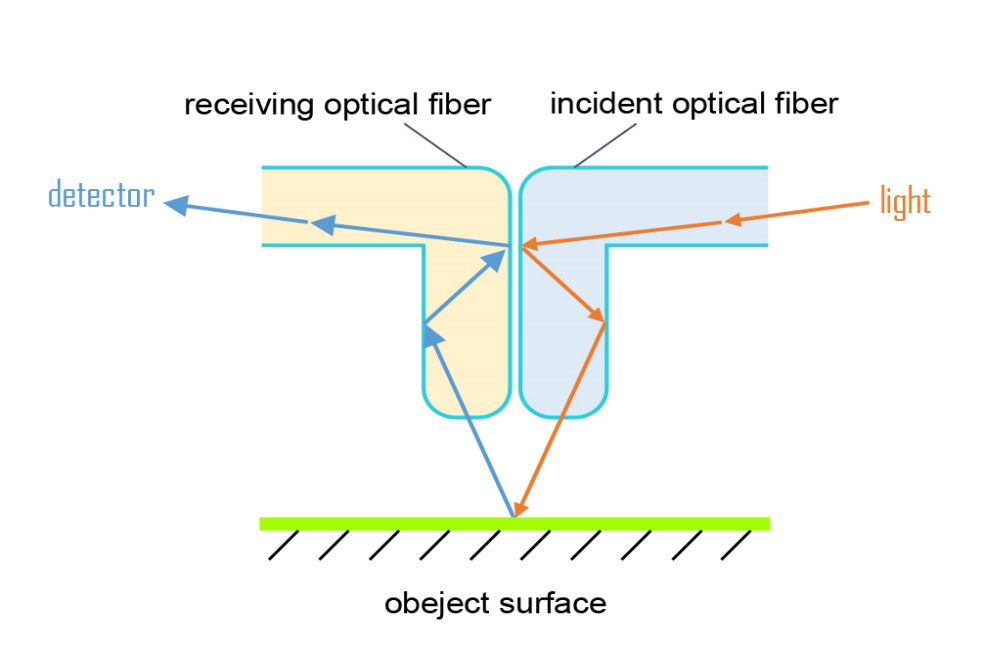

The optical fiber sensor is composed of light source, incident optical fiber, receiving optical fiber and photoelectric detector, as shown in Figure 3. The probe of optical fiber sensor is composed of a incident optical fiber and a receiving optical fiber. The light from the light source is sent to the tested object through the incident optical fiber. The receiving optical fiber receives the light reflected from the surface of the tested object and transmits it to the photodetector, which converts the light signal into a voltage signal for output.

The X-ray attenuation formula is:

I=I0exp(-ud)

Among them, I0 and I and are the intensity before and after X-ray penetrating the object, u is the attenuation coefficient, and d is the thickness of the penetrated object.

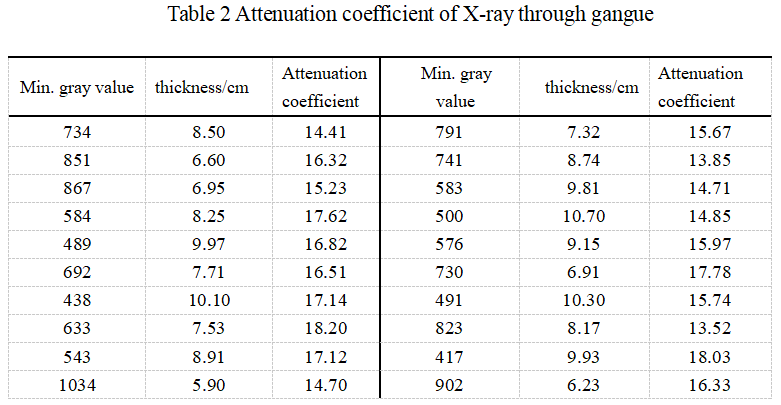

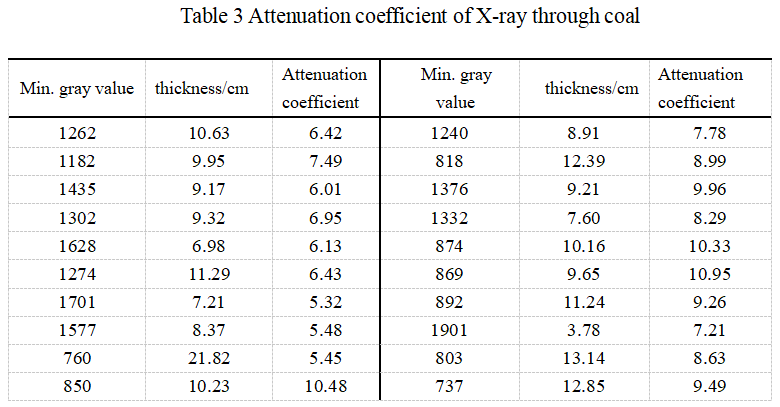

The experimental data shows that the attenuation coefficient of X-ray passing through coal is less than 11, and the attenuation coefficient of X-ray passing through gangue is more than 11, which indicates that the setting of gangue recognition domain is reasonable and effective.

Conclusion

Based on the technology of X-ray and optical fiber sensor, XRT intelligent dry coal separator obtains the X-ray images of coal and gangue by X-ray scanning, and obtains the gray value of the image after processing. It uses optical fiber sensor to detect the thickness of coal and gangue, determines the recognition value of coal and gangue by gray value and thickness, eliminates the influence of different thickness of coal and gangue on recognition, and effectively realizes the automatic separation of coal and gangue.

If you're interested in the HXS intelligent separator, pls just contact us:

Teresa Zheng

Tari Wang

E-mail

teresa.zheng@hot-mining.com

tari.wang@hot-mining.com

Tel

+8615281626323

+86 15927439651

|

|

Teresa Zheng |

Tari Wang |

|

|

teresa.zheng@hot-mining.com |

tari.wang@hot-mining.com |

|

Tel |

+8615281626323 |

+86 15927439651 |

Please feel free to give your inquiry in the form below.We will reply you in 24 hours.