Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

Mine intelligent mining overall solution ---- wireless remote control automation series

Mine professional line of sight wireless remote control system

Mine wireless remote control system based on WIFI and other wireless communication technology and Canada mine wireless remote control system security control strategy, for various types of mining machinery, to provide wireless remote control solutions. Operators to array remote control unit, within 100m away from the mining equipment, through the eyes around the situation, remote operation, to achieve a variety of functional equipment action.

Plan1 Remote control system of roadheader

Features:

1. Meet the mining requirements of hazardous

areas, to ensure personal safety.

2. Wireless remote control is simple,

action sensitive and reliable.

3. Remote control equipment, stable and

reliable, maintenance and replacement components are very convenient.

4. Wireless remote control device using

frequency time-division system, wireless signal stability, anti-interference

ability.

Use range:

Mine boring machine (various brands,

various models)

Remote control function:

1. Proportional control: left track advance

and retreat, right track advance and retreat, boom lift, boom around, star

wheel speed.

2. Switch control: system start and stop,

bell, star wheel positive and negative, shovel

plate lift, back support lift, transport

around, transport lift, a transport positive and negative

start, two transport start and stop,

cutting telescopic, cut low-speed start and stop,

cut high-speed start and stop, pump start

and stop, spray start and stop, emergency stop button.

Plan2 Loader remote control function

Remote control function:

1. Proportional control: left, right, lower

arm, lift arm, loading, unloading, throttle control, forward control, backward

control.

2. Switch control: Speaker, remote manual

switch, front light control, rear light control.

Plan3 Remote control function of scaling

jumbo

Features:

1. To meet the mining requirements of

hazardous areas to ensure personal safety.

2. Wireless remote control is simple,

action sensitive and reliable.

3. Remote control equipment is stable and reliable;

maintenance and replacement of components are very convenient.

4. Wireless remote control device adopts

frequency and time system, wireless signal stability, anti-interference

ability.

5. Remote control and hand control function

freely switch, can be used for dangerous areas for unattended operation.

Use range:

Pile hair cart (various brands, various

models)

Remote control function:

1.Proportional control: left and right steering, left and right out of

the jack and retracted, NO.1 arm pitch, NO.2 arm pitch, turn left, turn

right,NO.3 arm pitch, hammer tilt, hammer swing, throttle;

2. Switch control: front / tail light, working / outrigger / running mode

selection, forward / neutral reversing switch, power switch, bulldozer lift,

two arms telescopic, broken hammer, start, stop, key switch, emergency stop.

Plan 4 Remote

Control System of Trolley

Underground electric locomotive remote

control system is the use of frequency conversion technology, micro-electronic

control technology, underground GIS technology, downhole high-precision positioning

technology and high bandwidth, high reliability networking technology, combined

with production scheduling optimization model to achieve underground electric

locomotive remote control and speed cruise Self-running. The system satisfies

the trend of mining modernization, laying an important foundation for digital

mining.

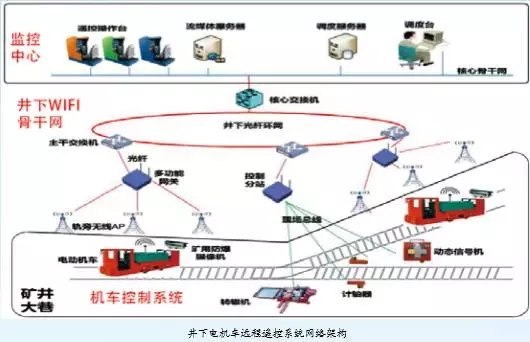

The system consists of monitoring center,

underground WIFI backbone network, locomotive control system composed of three

parts, the network architecture as shown above monitoring center includes:

remote control console, media server, scheduling server, scheduling, PC

monitoring software. Downhole WIFI backbone network includes: core switches,

backbone switches, multi-function gateway, WIFI base station. Locomotive control

system includes: locomotive controller, mine explosion-proof camera, dynamic

signal machine, switch machine, axle counter.

System functions:

1. the system can accurately detect the

locomotive position and track occupancy, underground production-related information

through the wireless network to the monitoring center, to achieve optimal

scheduling of production operations;

2. Real-time detection of ore / ore

discharge point of material information, to achieve locomotive and ore /

discharge of the precise control;

3.Combine the locomotive position

information and operation plan to realize the correct linkage of the turnout

and the remote control driving of the locomotive, and realize the remote

control, self-running and manual driving seam switching;

4. Collecting the locomotive itself status

information and track information, the status of the electric locomotive itself

and safe driving a comprehensive diagnosis;

5. Can accurately record the operating data

of electric locomotives to achieve with the mine management and production

performance management;

6. Can be more convenient and accurate

grasp of the overall load of the electric locomotives, the maximum play the

transport capacity of the train.

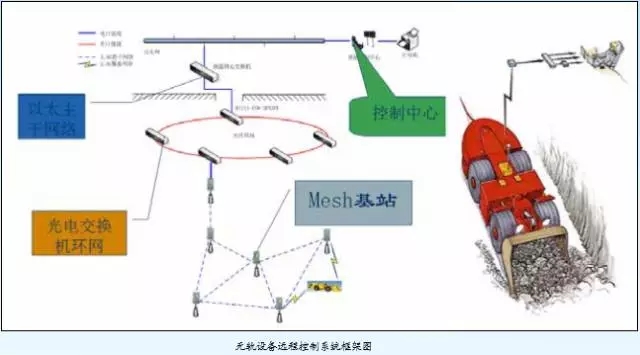

Plan5 Remote control system for trackless

equipment

It is mainly used in the remote remote

control environment of metal mine and nonmetallic mine. Under this environment,

the remote MESH network based on WLAN technology standard or 3G / 4G wireless

communication network can realize the remote control management of the vehicle.

Features:

1.One to one remote control:telecontrol

unit remote control of a variety of mobile machinery downhole through the

remote control handle, foot pedal, buttons, etc., to achieve the desired

function of action.

2. Multi-machine control: remote control

system can achieve one-to-many control. In one-to-many control, a remote

control handle unit or remote control seat can control two or more locomotive

units makes the locomotive joint operations to improve production efficiency.

3. Locomotive navigation: based on 2.4G

wireless local area network, ELinkCS locomotive autonomous navigation

algorithm, laser scanning recognition system can realize the scraper autonomous

navigation function. In the scraper loading and unloading can be completed after

the autonomy to the loading area or discharge Area. So as to realize the high

efficiency ore-discharging work of the scraper on the mining method of the

metal mine.

Main functions:

1. Remote control: by the control center to

send commands, remote control drilling rig, excavator for a variety of actions.

Including forward, reverse, throttle, turn left, turn right, boom, arm,

loading, unloading, parking brake, auxiliary brake, fire, engine start, speed,

emergency stop, headlights, rear lights, speakers And various protection

measures;

2. Video surveillance: locomotive front and

rear were installed network camera for remote monitoring of the working

environment. The camera should be dust-proof processing, the video data

directly through the 4G network to upload to the monitoring center;

3.Sound and light alarm: when the

locomotive running condition monitoring parameter exceeds the set threshold,

the car mobile terminal issue sound and light alarm, while the alarm upload to

the monitoring center;

4. Driving record: the car mobile terminal

automatically records locomotive running a variety of actions and status,

similar to the black box. When the locomotive failure can be read directly

through the serial port. Including: oil pressure, oil level, engine

temperature, transmission oil temperature, gearbox oil pressure, brake oil

pressure, brake oil level, fuel tank level, mileage, driving time, engine

working condition, braking state, Neutral state, locomotive forward, backward,

throttle, turn left, turn right, lift arm, lower arm, loading, unloading,

brake, fire, engine start indication, etc.

5. Path learning: locomotive installation

mode switch (manual, learning, remote control). Selecting the learning mode,

the operator driving the locomotive in the planning of the road on the model of

travel, and the on-board mobile terminal records relevant information for use

in autonomous navigation.

6. Autonomous navigation: by the monitoring

center to send instructions to the locomotive work in autonomous navigation

mode. In the autonomous navigation, the vehicle-mounted mobile terminal

autonomously travels according to the learned route. Through the odometer and

GPS to determine the exercise distance, the angle sensor to adjust the

attitude, the front part of the installation of the laser scanner to identify

roadblocks scanning and the corresponding treatment. Autonomous navigation with

a driving safety zone, alarm zone, dangerous parking area identification;

7. Manual intervention: autonomous

intervention allows manual intervention, that is, through the monitoring center

to send manual intervention instructions, by the mobile terminal analysis and

execution of the command;

8. Operating mode: locomotive has a variety

of operating modes, including: manual control, path learning mode, remote

control mode. These three modes are switched on and off in the locomotive, when

you select the remote control mode, you can choose whether to enable autonomous

navigation mode, automatic discharge mode in the monitoring center;

Use range: Scraper, drilling rig and so on.

Contact us:

|

|

Serena Fu |

Kira Zhang |

|

|

serena.fu@hot-mining.com |

kira.zhang@hot-mining.com |

|

Skype |

Serena20140924 |

kira.zhangjing |

|

+86 151 0833 3341 |

+86 152 8105 1932 |