Company:Chengdu Cobalt Mining Co., Ltd

Email: sales@hot-mining.com

Phone:+86 28 83311885

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

Research of Fully Mechanized Mining Technology of Ultra thin Coal Seam and It s Application

Jito Jin, Coal Mining Engineer, HOT Mining

0 Introduction

For a long time, because of the working face with ultra thin coal seam(below 0.8m) is extremely narrow, and high labor intensity of worker, poor working condition, difficulties of equipment assorted, poor adaptation ability to geological structures such as the thickness of coal seam, angle changes and faultage. Moreover the input output ratio is high with low efficiency, economic efficiency is poor, so lots of areas gave up of ultra thin coal seam mining that the fully mechanized ultra thin coal seam mining development is slow.

Ultra coal seam mining method : (1) Blasting mining, blasting down coal, hand loading coal, single hydraulic prop. The production efficiency of this method is low, security is poor and high labour intensity. (2) High-grade general mining, cutting coal and loading coal by off pan shearer, single hydraulic prop. Drilling and blasting and artificial coal shovel process are reduce in this way, but working face control more difficult, poor security, and need more people, production capacity is difficult to get into full play.

In China most of ultra thin coal seam working face by blasting method, only a few part use the high-grade general mining method. And ultra thin coal seam mining technology is still blank. Therefore, based on the research of ultra thin coal seam mining roof limited deformation and control theory, the movement rule of overlying strata, reasonable working resistance of hydraulic support, Sichuan Dazhu Coal Electricity (Group) Co., Ltd. developed the full mechanized coal mining equipment applicable for ultra thin coal seam. And it’s application in Binlang coal mine N2211 working face that got good results.

1 The way of ultra thin coal seam mining technology

Existing fully mechanized mining equipment includes:

(1) Auger shearer

Auger shearer is transform from auger drill which is used for opencast mine. The output level of the working is low when use the auger shearer only. At present it’s not used in the main mining working face, mainly used for the recovery of residual coal.

(2) Coal plough

The coal plough has the advantages of high work efficiency, simple structure, easy maintenance, etc. China has used to plough mining ultra thin coal seam testing, but the results are found to be affected by the the thickness of coal seam, the dip angle, the top floor condition, and the special geological structure, so that it didn’t get popularization.

(3) Single drum Off pan shearer (single drum)

In 2006, Sichuan Dazhu Coal Electricity (Group) Co., Ltd. carried out the test of single drum off pan shearer and found that the unit’s adaptability is very poor, not adapt to the development of modern coal mining machine production technology requirements.

(4) Supporting equipment

China currently has a series of hydraulic support product which are suitable for different geological conditions, different equipment of thin coal seam working. But the scaffold height adjustment range is small, thin seam adaptation ability is poor so that its unable to meet the ultra thin coal seam to pedestrians, machine and a coal space requirements.

(5) Scraper conveyor

The scraper conveyor in thin coal seam working face is basically able to meet the production needs of the mining ares. But most of these scraper conveyor’s groove is wide, the middle plate is thick and the distance from the bottom is high. If used in ultra thin coal seam working face, it will reduce the pedestrian space and scraper conveyor section coal. Therefor, scraper conveyor is not suitable for application in the ultra thin coal seam working face.

Above all, its difficult to achieve fully mechanized mining in ultra thin coal seam with existing equipment . Must be a full range of research from the device structure, supporting parameters and automation, the key technology is development of ultra thin coal seam mining hydraulic support, coal shearer and scraper conveyor, the overall matching of fully mechanized coal mining equipment and efficient fully mechanized production process.

The direct roof and floor of the Sichuan Dazhu Coal Electricity (Group) Co., Ltd.’s mining area is mainly mud rock, it’s be easier when coal shearer cutting the rock through faults. In appropriate increase of shearer cutting ability of the premise, can achieve fully mechanized mining with under complicated geological conditions. Therefore, the company has carried out the following studies:

(1) Developed MG 110/130 TPD Off Pan Shearer (Electric traction), it’s cutting ability of rock is great, ensure the shearer in complex geological conditions can cut the rock directly, and make working face does not move, no blasting or less blasting.

(2) Developed ZY2400/5.5/12 laminated beam double prop shield type hydraulic support which is high expansion ratio. The height of the support is 550~1200 mm by whole stack top beam structure which can decrease the beam thickness and increasing the space for machine.The adoption of articulated link type bottom adjusting mechanism to meet the conditions of large inclined angle coal seam mining. Using cluster multi-core high pressure pipe and adjacent - frame pilot control mode not only safe and reliable also working space is large.

(3) Developed SGB520/ 255 high strength narrow groove edge double chain scraper conveyor. The conveyor height is low - 180mm, width is small - 500mm, so the transportation section is increased, and the control roof distance of the support frame is reduced. The scraper conveyor is also equipped with a movable protective device which can prevent fly-rock and improve loading effects.

(4) Equipment matching and parameter optimization for off pan shearer, scraper conveyor and hydraulic support are achieved that solved the contradiction between device geometry parameters and equipment capacity and reduce the size of the equipment, and increase the coal, machine and working area.

2 The application of fully mechanized mining technology of ultra thin coal seam in the Bin Lang Coal Mine.

2.1 Overview of Bin Lang Coal Mine N2211working face

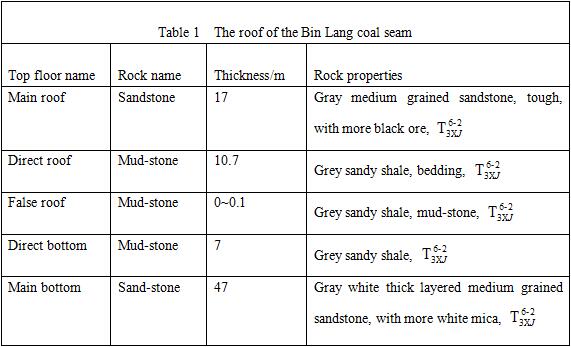

Bin Lang Coal Mine N2211 is ultra thin coal seam working face, its strike length is 330m, the length is 90, thickness is 0.75~1m, the average thickness is 0.8m, the coal seam dip angle is 13~27, hardness f=1.91 is soft to medium hard coal seam. The roof of the coal seam is shown in Table 1.

2.2 Fully mechanized mining main equipment

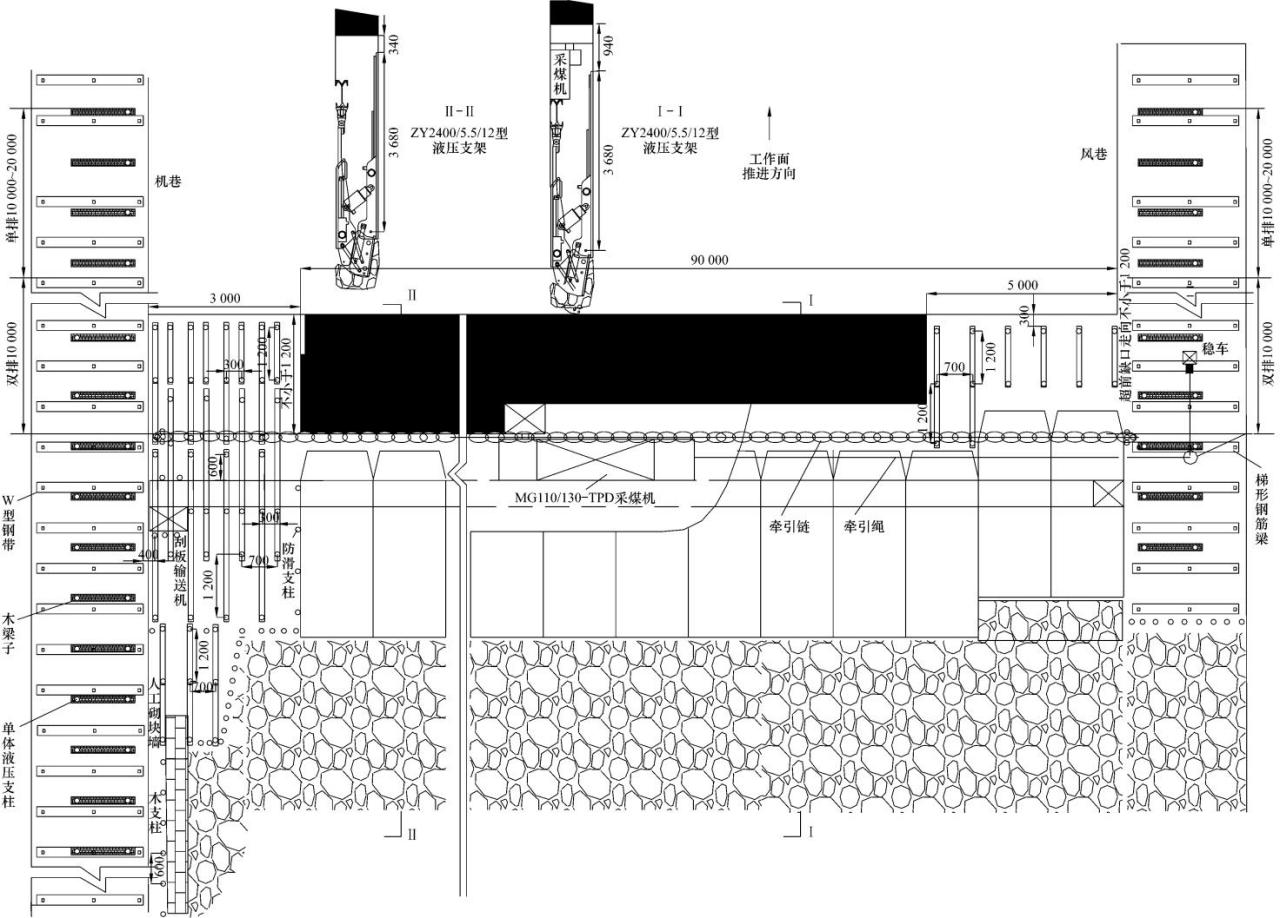

N2211 working face fully mechanized mining equipment: MG110/130 - TPD Off Pan Shearer, ZY2400/5.5/12 Hydraulic Support (two prop shield type), SGB520/255 Scraper Conveyor, SZB630/40 Groove Scraper, DSJ65/20/240 Belt Conveyor.

2.3 Arrangement of working face

N2211 working face with a long wall backward mining, all caving method to deal with mined out area of fully mechanized mining method. Its layout as shown in Figure 1, the length of the units are mm.

Figure 1 Arrangement of N 2211working face

2.4 Fully mechanized mining technology

2.4.1 Coal mining technology

Working face once mining full height, when the coal seam thickness is not up to the minimum requirements the coal shearer cutting the bottom to make the thickness to meet the requirement. The main working procedure for cutting coal, sliding, shift, end head maintenance, equipment maintenance, opening gap, etc. Main process: cutting coal, shifting, shifting scraper.

2.4.2 Up and down lead gap

Gap parameter: Top lead gap inclination length is 6m, strike length is 1.2m, down lead gap inclination length is 4m, strike length is 1.2m.

Support method: Single beam and four pairs of eight beams, hinged beam with each other.

Blasting method: Using MZ-12 coal drilling, hole three eyes presbyopia, depth of 1.4m, with three coal mine permissible explosives and millisecond delay electric detonator 1~5 initiation, demolition, series connection.

2.5 Application effect and benefit

In the normal production process of the N2211 working face, 8 cuts a day, each cut 0.6m, coal bulk density is 1.35t/m3, daily output = length × cutting height × cut footage × number of cut × unit weight of coal × working face extraction rate = 90 × 0.8 × 0.6 ×8 × 1.35 × 0.98 = 457 t. Monthly output = daily production capacity×monthly working day×normal cycle = 457 × 30 × 0.9 = 12339 t.

Table 2 Comparison of the production capacity of N2211 in July 2009 and July 2010 using fully mechanized mining and blasting mining technology.

Method

Daily Max yield/t

Daily yield /t

Monthly yield/t

Annual yield/t

Fully mechanized mining

500

457

12339

148068

Blasting mining

280

165

4950

59400

From Table 2, under the same conditions the maximum daily yield, the average daily yield, average monthly yield, average annual yield of fully mechanized mining face is blasting mining face 1.79 times, 2.77times, 2.49 times, 2.49 times.

In the coal market price (including clean and midding(coal) ) is 680 yuan/T, N2211 working face of the blasting mining technology at the value of 40 million 392 thousand yuan, the annual yield value of 89 million 499 thousand yuan for fully mechanized coal mining technology, under the same conditions, the output value of fully mechanized increased 49 million 107 thousand yuan.

3 Epilogue

Sichuan Dazhu Coal Electricity (Group) Co., Ltd., developed the application of ultra thin coal seam mining equipment and the high efficiency of fully mechanized mining technology in mining area was first time realized in 0.55~0.8 m seam to effectively improve the efficiency, mechanization and automation of coal mining in ultra thin coal seam working face. In the concrete application, it is necessary to study the technology of the drum height adjustment of the coal mining machine, in order to improve the ability of coal mining machine to adapt to the change of coal thickness. Further research on how to reduce the workload of the end opening gap, to achieve the coal mining all cut through the face of coal wall as far as possible. And doing research on automation technology, on the basis of adequate pedestrian space to achieve the electro-hydraulic control of the hydraulic support.

Contact us:

|

|

Serena Fu |

Kira Zhang |

|

|

serena.fu@hot-mining.com |

kira.zhang@hot-mining.com |

|

Skype |

Serena20140924 |

kira.zhangjing |

Please feel free to give your inquiry in the form below.We will reply you in 24 hours.