Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

Study on Solving the Environmental Protection Problems in the Process of Gold Mine All Slime Cyanidation Carbon Pulp

Abstract:In view of the environmental protection problem of a gold mine in Shaanxi province, It studied on the transformation of a number of mineral processing technology, finally, the flotation concentrate cyanide process is used to replace original All Slime Cyanidation Carbon-in-leach (“CIL”), and increased cyanide slag treatment process. The production practice shows that to solve the problem of environmental protection and to improve the recovery rate, reduce the operation cost of the enterprise.

Cyanide Leaching is the main method of extracting gold and silver in the world, but this method needs highly toxic sodium cyanide as the raw material, which will produce a large number of wastewater and tailing slurry containing cyanide and metal in the production process. Today, with the increasingly strict requirements of environmental protection, mining enterprises are facing more and more pressure of environmental protection. The gold mine in Shaanxi Province is located in the south of Qinling Mountains, with special geographical location and strict environmental protection requirements. Before the technical transformation, the mineral process is “CIL”, which produces about 10000m ³ of cyanide bearing tailing pulp every day. At the same time, there are three mineral processing plants, each of which has two sets of all slime cyanidation carbon pulp gold extraction systems, with many production systems, high cost and difficult management. Therefore, it is urgent to improve the mineral process, solving environmental protection problems as soon as possible, and bring better social, safety and environmental benefits to the company and its surrounding environment under the conditions of feasible technology and reasonable economy.

1 Ore Property

The ore belongs to gold ore with less sulfide. The content of metal minerals in the ore is very small, accounting for 2.71% of the relative content of minerals, and the content of metal oxides is only 0.01%. The metal sulfides are mainly pyrite and a small amount of pyrrhotite, accounting for 2.61% and 0.07% of the relative content of minerals, respectively. The non-metal minerals are mainly quartz and albite, followed by dolomite, calcite, a small amount of sericite and apatite. The gold deposits are mainly natural gold, a small amount of silver gold, a small amount of tellurium gold and silver. See Table 1 for multi-element analysis results of R.O.M ore.

2 Analysis on The Necessity of Technological Transformation

2.1 Environmental Protection Re quirements

Now the tailings pond used by the company is close to the closure period, but the newly built tailings pond has not been treated with anti-seepage treatment.

2.2 Three Mineral Processing Plants Have High Production Cost and Complex Management.

Now there are three mineral processing plants in the company, the mineral process is “CIL” gold extraction, and each mineral processing plant has two sets of “CIL” gold extraction systems, The production system is numerous, with high cost and difficult management.

2.3 The Grinding Particle Size is Coarse and the Recovery Rate is Low.

The three mineral processing plants have been transformed for many times to reach the current processing capacity. In order to complete the production tasks of the group company, it is necessary to maintain the existing high load production status for a long time. At the same time, the grade of raw ore decreases year by year, the ore properties are complex and changeable, and the recovery rate is low.

3 Exploration and Practice of Technological Transformation

3.1 Practice of Mineral Process Transformation

Based on the summary of the previous work, the transformation of mineral process is carried out. Through the comparison and demonstration of multiple schemes, the final mineral process is flotation concentrate cyanide process.

3.1.1 Details of Mineral Process Transformation

1) Crushing Process

In this technical transformation, the existing crushing process of #1 and #3 mineral processing plant is fully utilized, and the crushing process of #1 mineral processing plant and #3 mineral processing plant is maintained. The new fine crushing equipment is designed to make the total crushing capacity of #1 and #3 mineral processing plant reach 5200 t/d.

2) Grinding and Classification Process

Combined with the production situation on site, the grinding classification process of this technical transformation is a closed circuit, and the final overflow fineness of grinding product classification is - 74 μm, accounting for 55%.

The grinding products of #1 and #3 mineral processing plant flow to the mixing tank of the flotation workshop and enter the flotation operation.

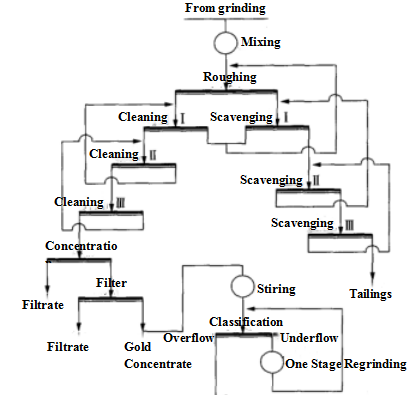

3) Flotation Process

The flotation plant uses the existing carbon leaching plant, the pulp is stirred and stirred by stirring tank, and then is added to the roughing 2 slot 70 m3 flotation machine. The coarse tailings are entered into the 6 slot 70 m3 flotation machine for three times scavenging. The flotation fan and reagent addition and preparation are centralized outside the flotation workshop, which can avoid the noise and reagent pollution in the workshop and greatly improve the working environment of workers.

4) Dewatering of Flotation Concentrate

The flotation concentrate is sent to the original Φ20 m thickener by slurry pump for concentration and dehydration. The underflow of the thickener flows to the 45 ㎡ ceramic filter for secondary dehydration. The overflow water of the thickener and the filtrate of the ceramic filter return to the grinding and flotation operation.

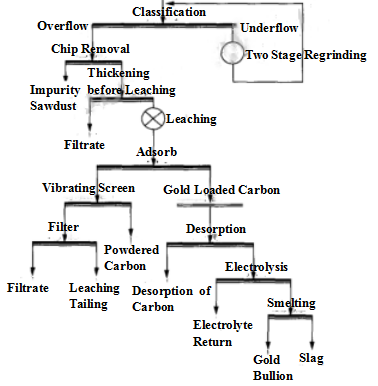

5) Cyanide Residue Dehydration of Flotation Concentrate

The cyanide residue of flotation concentrate flows automatically to the newly built cyanide residue dehydration workshop of flotation concentrate for pressure filtration, and the return water flow is not discharged outside. The dehydrated cyanide residue is transported to the dry pile of tailings pond by car. In the design, the cyanogen breaking treatment process is added, and the cyanogen reducing treatment is carried out for the cyanogen slag of flotation concentrate regularly to avoid the adverse effect of return water on the mineral processing index.

See Fig.2 for the flow chart of the raw mineral processing.

4 Conclusion

4.1 The production practice shows that the selection and configuration of mineral process is reasonable, the process index is advanced, the operation cost is reduced, and the competitiveness of the enterprise is increased. All indexes of the mineral processing plant run well and meet the design requirements. In 2014, the comprehensive recovery rate of ore dressing was 74.42% before the technological transformation, 76.21% after the technological transformation, and the recovery rate increased by nearly 2 percentage points; the direct cost of ore dressing decreased from 47.52 t to 43.86 t. The annual income of the company is about 10 million yuan.

4.2 Through the implementation of the project, the potential environmental damage and safety production hazards caused by the 10000 m/d cyanidation tailing pulp of the enterprise are solved, the pressure of environmental protection for the production of the enterprise is reduced, and the problem that the discharge of cyanidation tailing pulp fails to meet the standard and the new warehouse cannot be used is solved; the resource utilization efficiency is improved and the production cost of the enterprise is reduced. The social, environmental and economic benefits of the project are outstanding, which are the concrete actions to implement the national policies on mine environmental governance.

4.3 At present, the environmental protection requirements are increasingly strict. This achievement has a very exemplary and pioneering role in domestic metal mines, and has a broad application prospect.

Contact HOT For Your Mine Projects

Teresa

Email: teresa.zheng@hot-mining.com

Tel/Whatsapp: +86 15281626323