Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

|

|

|

|

|

||

|

HOT complete longwall coal mining units represent the ultimate solution for high-production low coal seam longwall mining. HOT incorporates best-in-breed low coal seam coal shearers, roof supports, armed face conveyors(AFC), bridge stage loaders(BSL), crushers, and belt conveyors to deliver a complete low coal seam longwall coal mining units. |

HOT Mining is leading in the design, construction and operation of coal washing plants (coal handling and preparation plants, hereafter “CHPP”).The Joint Venture of HOT – SCCDRI has delivered over 20 CHPPs with capacity from 90 TPH to 3125 TPH. |

|

|

|

|

|

|

|

|

|

|

||

|

Train/Truck Loading Station(TLO) is an important bridge to connect the raw bulk material and steel industry and energy suppliers. The bulk material is discharged from weighing hoppers and top loaded into wagons ready to carry the goods to the customers. |

|

Longwall Top Coal Caving (LTCC) is a special designed longwall mining method for very thick seams where good quality coal is being left because "conventional" longwall equipment has not yet been designed to operate successfully beyond around 5m mining height. |

|

|

|

|

|

|

|

|

Steeply Inclined Seam Longwall Mining Projects |

|

|

|

According to the angle size, Chinese coal industry could be divided into the following stype: nearly-horizontal coal seam if the dip angle <12°, gentally-inclined coal seam if the dip angle is between 12°~25°, inclined coal seam if the dip angle is between 25°~45°, steeply-inclined coal seam if the dip angle >45°. |

|

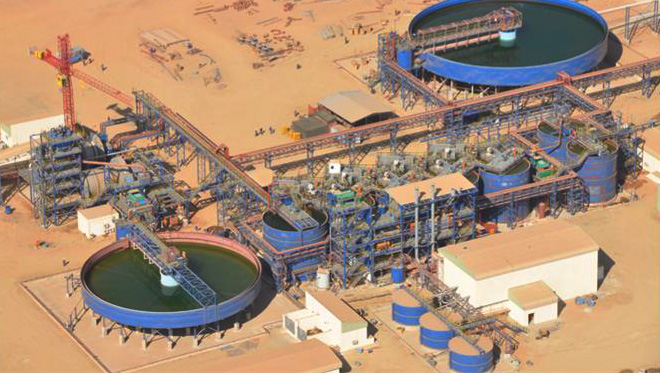

Gold Carbon-in-pulp (CIP) production is the sequential leach then absorption of gold from ore. During the CIP stage, pulp flows through several agitated tanks where sodium cyanide and oxygen have been added to dissolve gold into solution. |

|

|

|

|

|

|

|

| Pipe Belt Conveyor’s Technical |

|

|

|

Pipe belt conveyor’s head, tail, loading and unloading part have the same structures with the ordinary ones. The main differences are: after the loading zone of conveyor’s tail, the belt has a gradual shape transition, from flat to trough and trough to deep trough, then material is wrapped into a pipe. |

|

The flotation method is a widely used technique for the recovery of gold from gold-containing copper ores, base metal ores, copper-nickel ores, platinum group ores and many other ores where other processes are not applicable. |

Contact us:

|

|

Serena Fu |

Kira Zhang |

Lolita Liao |

|

|

serena.fu@hot-mining.com |

kira.zhang@hot-mining.com |

lolita.liao@hot-mining.com |

|

Skype |

Serena20140924 |

kira.zhangjing |

lolita.liao918 |