Mining Process Equipment

strategic partnership agreements,China's mining sector,industry Leaders

q,qa,a,sd,asdf

strategic partnershi

China's mining secto

mining industry,tech

internationalization

China Mineral Proces

future development,C

Nanchang Mining Mach

technological innova

China Metallurgical

Air Purification,Ind

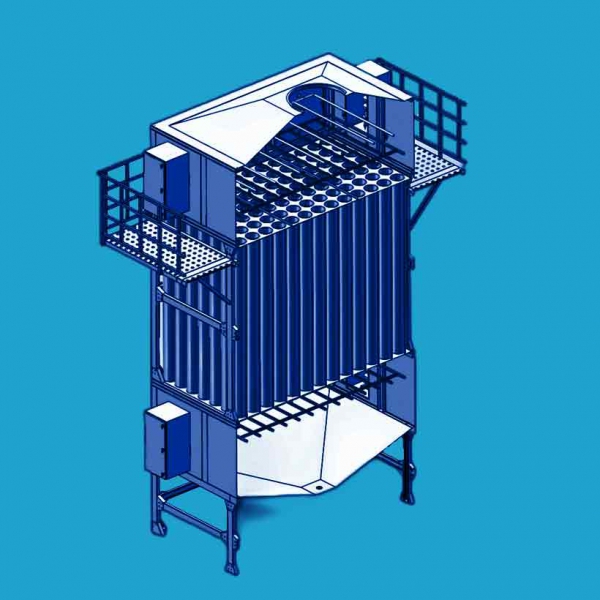

High-efficiency exha

Industrial Waste Gas

activated carbon ads

At present, the most advanced crusher technology in limestone mine is to use jaw crusher for primary crushing and double-geared roller crusher for secondary crushing. Compared with other secondary crushers, the lump forming rate of the output of the double-geared roller crusher is increased by 15% - 25% (3cm ~ 9cm blocks), which can improve the economic value. According to the different hardness of limestone, the double-geared roller crusher has many advantages such as high reliability, strong stability and good performance on saving cost. Our gear roller is made of Babbitt high-strength wear-resistant alloy, and its service life is 2-3 times longer than that of common material. According to the current customer use, the spare parts need to be replaced after 3-5 years of use. The replacement cycle of spare parts is long and the continuous production is reliable.

MESPROCESS Double-geared Roller Crusher is a mature and advanced classification crusher, which has been finalized after more than 10 years of continuous research and innovation. It can adapt to all kinds of harsh environment and can strictly guarantee the product granularity, high block rate, very low over crushing rate and high material roundness after crushing. It is mainly used in coal, coke, gangue, limestone, calcium carbide and other materials under the primary crushing, secondary crushing operation, which is widely used in coal, building materials, metallurgy, chemical industry and other industries.

|

Name |

Unit |

Parameters |

|

Material |

|

limestone |

|

Feed size |

(mm) |

≤300,few: 350 |

|

Discharge size |

(mm) |

≤80 |

|

Treatment capacity |

t/h |

1000 |

|

Crushing strength |

MPa |

≥200 |

2.3.1 The crushing gears are cast with high wear-resistant alloy; the advanced casting and heat treatment technology realizes the perfect combination of high strength, high toughness and high wear resistance; its service life is 2-3 times that of high manganese steel and alloy steel commonly used in the industry.

2.3.2 There are many kinds of crushing tooth structures, such as movable tooth type, ferrule type, tooth ring type, tooth plate type and whole roll type, which can provide customers with the best cost-effective tooth structure according to working conditions.

2.3.3 The arrangement of crushing teeth is advanced, including large spiral, double spiral, multi spiral and linear type. It has the characteristics of high block forming rate and high crushing efficiency.

2.3.4 The product granularity is adjustable. There are three ways of adjusting the distance: eccentric cup adjusting distance, lead screw adjusting distance and hydraulic adjusting distance. The adjustment is convenient, the positioning is reliable, and the discharging granularity is strictly guaranteed.

2.3.5 The whole box structure is adopted in the crushing chamber, which effectively solves the problems of bearing positioning not firm and shaft skipping and shaft shifting in the split box structure, and realizes the sealing of the crushing chamber to ensure the cleanness of the working environment.

2.3.6 With the application of the expanding sleeve structure, the structure difficult to dismantle such as the coupling, the toothed roller and the belt pulley is innovated into the advanced structure of rapid dismantling.

3.2.7 A variety of walking structures can be selected: fixed type, lead screw type, hydraulic type and electric type, which is convenient for equipment maintenance.

2.3.8 Equipped with stall protection device, intelligent control system and intelligent lubrication system.

|

|

Tari Wang |

Tiffany Chen |

|

E-mail: |

tari.wang@hot-mining.com |

tiffany@miningmes.com |

|

Tel/WA: |

+86 15927349651 |

+86 18282103350 |

Monica

Monica

Gary

Gary

Technician

Technician

Sarah

Sarah

Ben Zhao

Ben Zhao

ASTA(Dubai)

ASTA(Dubai)

Home

Home