Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

The reasons of gold refractory, ore classification, and preprocessing methods.

I. The reason of the gold mineral refractory

There are so many types of reasons that caused the difficulty of gold ore processing, including physical element, chemical element, and mineralogical element. In summary, the difficulties consist of the following conditions.

1. Physical encircle

The gold is fine-grained or microscopic granular in the gold ore, and it is surrounded or infected in sulfide minerals(such as pyrite, arsenopyrite, pyrrhotite), and silicate ore(such as quartz), or it is in the sulfide mineral crystal structure. The dissociation is also difficult for the surrounded ore by using fine grinding, and it caused that gold can't contact with cyanide.

2. The side effect of Oxygen and cyanide consumption minerals.

In the mineral ,there are always metal sulfides and oxide, such as arsenic, cooper, antimony, iron, manganese, plumbum, zinc, nickel, cobalt, etc. They have a high solubility in the alkaline cyanide, have a large amount consumption of cyanide and dissolved oxygen in the solution, forming a variety of cyanide complex compound and SCN-,therefore, it affects the oxidation and the leaching of gold. The most important oxygen consumption minerals in the ore are pyrrhotite, marcasite, arsenopyrite. The most important cyanine consumption minerals are arsenopyrite, cooper prrites, bornite, stibnite, and galena.

3. Gold particles to be coated

In the process of cyaniding, gold grain surface contact with cyanide pulp, it may produce sulphide film, peroxide membrane(such as Calcium peroxide membrane), oxide film, Insoluble cyanide membrane, etc. And they make the metal surface passivation, significantly reduce the oxidation and the leaching rate of gold particles surface. If there is sulfide in the gold ore, the dissolution of gold will receive the influence of different forms, some specialists think it is because of the soluble sulfide (S2-or HS- ) after mineral dissolution, it can react with gold to form sulphide film, and cause the surface passivation of gold grain. But some other specialists think it is because that sulfide formed on the surface of a dynamic reduction galvanic, and it can cause compact cyanide complex film on the gold grain surface after its oxidation, so make gold passivation.

4. ‘Rob gold’effect of mineral substance

There are always some carbonic materials (such as activated carbon, graphite, humic acid) and clay in the gold ore. And they all easily adsorb on gold, these minerals can adsorb on gold cyanide complex in the process of cyaniding and leaching, that is ‘Rob gold’effect, make gold loss in the cyanide tailing, seriously affect the gold recovery.

5. In the form of dissolved gold compounds

Gold exists in some kinds of minerals in the form of antimonide,(such as calaverite, tellurium electrum, antimony tellurium gold, Tellurium copper and gold mine), solid solution electrum, and some other alloy, and their function is very slow in cyanide solution. In addition, the complex produced by the reaction of quodrate antimony gold ore, Black bismuth gold, gold and humic acid is difficult to dissolve.

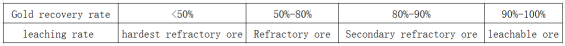

II. Classification based on leaching rate

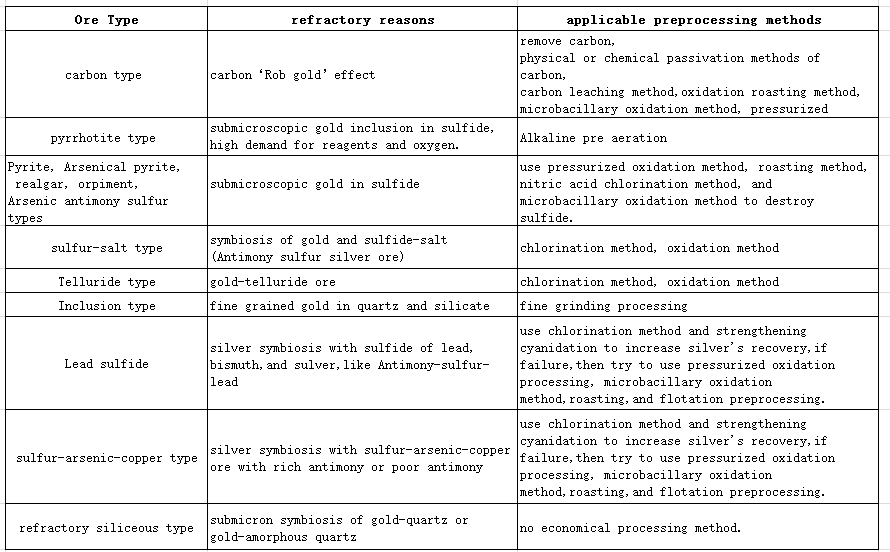

III. Classification of refractory ores

1. Carbonaceous gold ore.

There is organic carbon which can do‘Rob gold’in gold and silver ore, and it causes that gold is adsorbed in the cyanide solution, make ore difficult to cyanide and leach. Generally, we use roasting and chlorination pretreatment to destroy all or part carbon. Passivation mainly includes physical method to remove carbon, and using kerosene or similar inhibitors and Competitive adsorption to eliminate the activity of carbon.

2. Pyrite, Arsenical pyrite, realgar, orpiment, and Arsenic antimony sulfur gold ore

The most of refractory ore is gold bearing sulfide. Sulfide iron ore includes many kinds of pyrite and arsenopyrite. Ore and sulfide ore are symbiotic closely under submicron particle, we should make the sulfide oxidation by using roasting, pressurized oxidation, bacterial oxidation, chlorination oxidation. Compared with coarse pyrite crystals and arsenical pyrite, mildew globular pyrite is more suitable for using low temperature oxidation process, such as chlorination process and alkaline pre-oxidation process. But as for coarse pyrite crystals and arsenical pyrite, they require a stronger processing method, such as roasting, microbial oxidation, and pressurized oxidation. The processing character of other arsenic minerals is similar with arsenical pyrite character in any preprocessing condition as mentioned before.

3. Gold ore like pyrrhotite

In the heat, using alkaline air oxidation method is easier to complete alkaline pre-oxidation for pyrrhotite, so makes gold easier to cyanide and leach.

4. Telluride and sulfur-salt gold ore

In order to dissociate telluride and sulfur-salt and make the gold’ recovery easier, generally, we use hypochlorite chlorination processing, roasting, and pressurized oxidation, this condition of pressurized oxidation is not strict as the conditions of cubic crystal pyrite, arsenical pyrite, and other sulfide with arsenic.

5. Refractory siliceous gold ore

Submicron symbiosis of gold-quartz or gold-amorphous quartz. Gold is surrounded in the form of very fine particle size, it is not conductive to use an economical method for gold’s recovery.

6. Gold-silver ore like lead sulfide and sulfur-arsenic-copper types.

In these types of ore, silver is symbiosis with lead, antimony sulfide, and sulfur-arsenic-copper ore with antimony. If silver is the main economical mental, we can try to use medium preprocessing method, such as chlorination of ore or concentrate ore, soda leaching, and strengthening cyaniding leaching, if these methods were failed, it requires a more difficult preprocessing method if using cyaniding method for silver recovery, the preprocesses include roasting, pressurized oxidation, and microbacillary oxidation method. As for gold-silver ore, if gold is the main economical mineral, the preprocessing method is subject to gold’s recovery rate. In this condition, the best gold’s recovery rate may reduce silver’s recovery rate.

Contact us:

|

|

Serena Fu |

Kira Zhang |

|

|

serena.fu@hot-mining.com |

kira.zhang@hot-mining.com |

|

Skype |

Serena20140924 |

kira.zhangjing |