Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

Why he becomes an instant hit at shanxi coking group

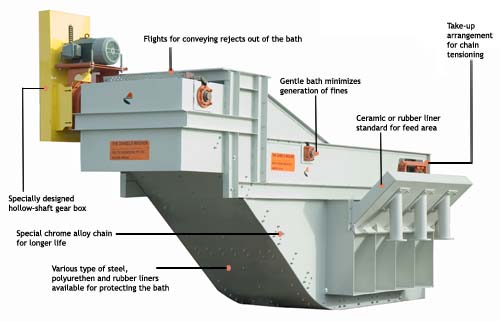

——The main advantages of dense medium vessel bath

In May 2013, Malan Coal Washing Plant, Xishan Coal Electricity Group of Shanxi Coking Coal Group Co., Ltd conducted the process technical transformation about dense medium vessel bath. After one year operation, the coal in the gangue has reduced from 8% to 1%, the recovered raw coal is 60,000 ton in 2014, and added 30 million benefit.

Due to the unadvanced coal washing process, the coal in the gangue takes large amount, which restricts the development of coal washing industry. In order to solve this problem, at the end of 2009, on the basis of investigation and survey, Shanxi Coking Coal Group Co., Ltd brought in the dense medium vessel bath technology, and tested in Xiegou Coal Washing Plant, Malan Coal Washing Plant, Xiqu Coal Washing Plant of Xishan Coal Electricity Group, Shanxi Coking Coal Group Co., Ltd and Lvneng Coal Washing Plant of Huozhou Coal Electricity Group of Shanxi Coking Coal Group Co., Ltd. “With dense medium vessel bath technology, the production efficiency has improved, the whole system operates well, reduced the coal waste, improved the process efficiency and accuracy”-Quoted by Mr. Jia Baolong, the Deputy Director of Malan Coal Washing Plant, Xishan Coal Electricity Group of Shanxi Coking Coal Group Co., Ltd.

As the professor of Coal Washing Major, the Deputy Chief Engineer of Coal Resource Comprehensive Utilization Department, Mr. Peng said, this technology has huge economic benefit and environment benefit, which could obviously improve the product quality and output.

Significant economic benefits. After the implementation of the heavy medium shallow slot separation in Ma Lan coal preparation plant, it has improved a lot compared to the past. The plant chief engineer Pang Liang said: "the original use of movable sievegangue coal and coal gangue with up to 8% - 9%, sometimes can reach more than 10% coal gangue. Gangue with coal on the economic efficiency of enterprises is a huge loss. After adopting the shallow slot separation technology, less loss of 60 thousand tons of raw coal per year. "Shanxi Lv Lin of Huozhou coal coking coal preparation plant Zhang Chunhui calculations: Shanxi coking coal Huozhou coal preparation plant of Lu Lin to a year into the washing capacity of 10 million tons, of which more than 50mm accounted for 2 million 500 thousand tons of coal, this part of the coal adopts shallow slot separation technology, the amount of gangue is about 600 thousand tons, according to the traditional process, gangue contains 5% with the amount of coal reached 30 thousand tons, per ton of coal is calculated according to the market price of 400 yuan, a year can save 12 million yuan. The use of heavy medium shallow groove separation technology, greatly improves the discharging efficiency, not only meets the needs of production, but also solve the problem of mine and coal preparation plant resources selection. Since the system has been running,Shanxi coking coal Xishan Coal and electricity Xi Qu coal preparation plant coal gangue with coal amount from the original 8.20% down to the present 0.93%. Shanxi coking coal Xishan Coal and electricity Malan coal preparation plant form 8% down to 1%. Shanxi coking coal Xishan Coal and electricity Dianxiegou coal preparation and Shanxi coking coal Huo Zhou Coal and electricity Lv Lin coal preparation plant coal gangue with coal loss close to 0.

Separation precision is improved. Liang Pang said: “ Especially for 02# coal and 2# coal, the quantity efficiency is very low when we used vibrating screen before. The quantity efficiency of 02# coal is around 63% while 2# coal is around 77%. After we adopted Heavy-Medium Vessel Bath Refuse Discharge Technology, the quantity efficiency is more than 95%.” After the operation statistics, 02#, 2# and 8# coal’s quantity efficiency of Malan coal preparation plant are greatly improved, respectively increased from 63.19%, 77.61%, 95.26% to 90.72%, 99.25% and 99.25%; the quantity efficiency of Xiqu coal preparation plant increased from 80% to 99.6%.

Good for the following production. Chunhui Zhang said: “In the past, coal washing plants worked without waste discharge system. The effect of separation was not good and the wear of equipments was very large. Dense medium vessel bath waste discharge system sets up a good foundation for cyclone and decreases the wear of equipments. ” The capability of main washing process can be fully developed with shallow slot separation technology. Less gangue will come into raw coal after separation. It will reduce the cost of main washing process when there is less gangue. The percent of gangue discharged by dense medium vessel bath is up to 30.31% in Shanxi coking coal Xishan Coal and electricity West Song coal preparation plant. It is increased by 11.63%. And it can reduce at least 100000 ton gangue coming into main washing process.

Labor intensity is reduced. “In the past, the vibrating screen and chute are always blocked, this increased our labor intensity. And the noise was too big. So we can not hand over to the next shift on time. But after using this system, our labor intensity, the dust and noise are redused greatly. The blocking and leaking situations are never appeared. So that we can hand over the next shift on time.” Said Mr Ji Mi who is the captain with 23 coal washing experience of prepare workshop production two team in Malan coal washing plant. With high degree of automation and processing capability, dense medium vessel bath can ruduce runtime effectively.

Environmental indicators compliance. Shanxi coking coal in Xishan Coal and Electricity Malan mine gangue hill is buried by loess gangue, at the foot of the gangue hill never appeared "gangue traffickers". Jia Baolong introduced: "In the past, a lot of trafficker on the gangue hill, often some people pick up gangue. Now, no one wants to come here, because there are no sources. " With the decrease of the amount of coal not only reduces the pressure on the management of gangue hill, but also to avoid the phenomenon of spontaneous combustion of coal gangue.

Contact us:

|

|

Serena Fu |

Kira Zhang |

|

|

serena.fu@hot-mining.com |

kira.zhang@hot-mining.com |

|

Skype |

Serena20140924 |

kira.zhangjing |

Please feel free to give your inquiry in the form below.We will reply you in 24 hours.