Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

Phosphate Flotation Production Line

Process Introduction

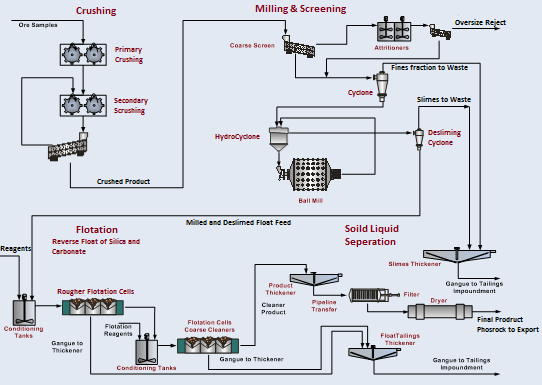

According to the different properties of phosphate ore, phosphate flotation technology has flotation process, gravity separation, scrubbing and mud removal; chemical leaching, combined beneficiation; photoelectric sorting, magnetic shield method, in which flotation process is common widely used phosphate rock sorting process, including direct flotation, reverse flotation, positive flotation process, and double reverse flotation process. In the reduction process, jaw crusher, impact crusher, and cone crusher are indispensable crushing plants. In the beneficiation process, there will be many other types of equipment applied such as classifier, screening machine, magnetic separator, sand washing machine and dryer etc. All these equipment consist of a whole complete production line.

Application

Phosphorite flotation product line is applied for complex structure phosphorite with fine particle distribution, closed embeddedness relationship, difficult monomer dissociation, etc.

Process Description

The process is generally used for the classification of low-grade phosphate rock, including the processing of of siliceous and silicon, calcium phosphate and calcium magnesia phosphate.The process must have a strong inhibition inhibitors used in conjunction with in order to get satisfactory results, is mainly used in the phosphate rock materials and fine disseminated gangue minerals.

Flotation process

Direct flotation inhibits gangue minerals by effective inhibitors, and the phosphorus mineral is enriched in foam by collecting agent. This process is suitable for low grade phosphate ores including magmatite type apatite and sedimentary metamorphic type phosphorite ore.

Reverse Flotation Process

Mainly used for the separation of phosphate and dolomite; dolomite is collected with fatty acid collector in weak alkaline medium, and the phosphorus mineral is enriched in the groove. The biggest advantage of reverse flotation process is the realization of the normal temperature flotation.

Double-Reverse Flotation Process

In alkaline conditions, double-reverse flotation makes the silicate surface positively charged, and the anionic collector separates minerals meaning floating dolomite firstly, and then reverse floating silicate; the product is heavy concentrate in groove; the production line can be carried out at normal temperature and coarse grain condition.

Process flow

Case (Phosphorite Flotation Equipment Production Line of Guizhou)

Processing materials: phosphorite ores

Production capacity: 0.18-7m3/min

Equipment configuration: electro-vibrating feeder, jaw crusher, ball mill, spiral classifier, mixing barrels, flotation machine, thickener, dryer, etc.

Production situation: Using coarse jaw crusher to do primary crushing at first, then fine jaw crusher will do secondary crushing to make sure the materials are in line with the ball mill feeding requirements. Put the materials into the ball mill to do grinding, after that using spiral classifier to classify the qualified materials. Next is adopting flotation machine to do flotation, then doing initial concentration by high efficiency thickener, the raw materials of phosphate ore needed for production are obtained after drying.

Contact us:

|

|

Serena Fu |

Kira Zhang |

Teresa Zheng |

|

|

serena.fu@hot-mining.com |

kira.zhang@hot-mining.com |

teresa.zheng@hot-mining.com |

|

Skype |

Serena20140924 |

kira.zhangjing |

terresa.zheng123 |