Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

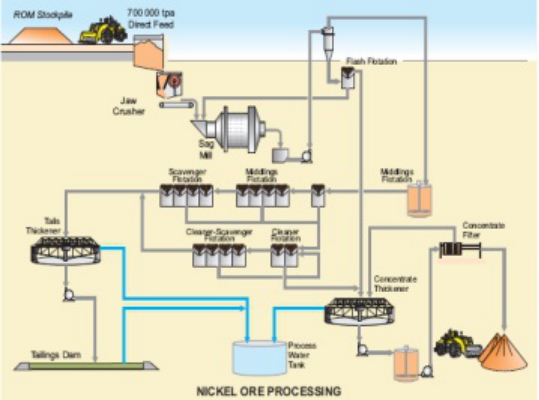

Nickel Ore Mining Process

Brief Introduction

Nickel ore mainly consists of copper-nickel sulfide ore and nickel oxide ore, beneficiation and processing of both methods is completely different. Copper-nickel sulfide ore beneficiation methods: The most important is the flotation. The magnetic and the gravity separation is usually secondary dressing method. Flotation copper sulfide nickel ore: often used in the flotation of copper sulphide minerals collector and frother.

Application

Nickel ore beneficiation can be applied to process copper nickel ore accompanied by Pyrite and other gangue or nickel oxide ore.

Process Introduction

Mixing Flotation Process:

The mixing flotation process is to separate nickel ore in which copper has lower content than Nickel, the mixed concentrate of copper and nickel will smelt into high grade nickel directly.

Mixing-preferably Flotation Process:

Copper nickel can be get from raw ore, then the copper concentrate with low grade nickel and the nickel concentrate with low grade copper can be separate from the mixing concentrate, the nickel concentrate will be sent into the next stop-smelting, nickel matte can be get and then it will be separated.

Mixing-preferably Flotation then Nickel Recovery:

When floatability difference happens to the various nickel elements in the raw ore, the nickel ore can be recycled from tailings after the copper and nickel did the mixing flotation.

Copper- Nickel Ore Flotation Process:

A basic principle of copper-sulfide nickel ore process is that it is better to let the coppers assimilate into the nickel ore. Because it is easier to recovery cooper from the nickel concentrate. The process has a best advantage-get the copper concentrate that has a low nickel rate directly.

Cases

For example, HOT Mining had a project in Sichuan province. After our service, the grade of the nickel concentrate is increased from 3.5% to 4.1%; The recovery rate of nickel increased from 77% to 80%; The magnesium oxide rate of the concentrate decreased from 17% to less than 10%; The recovery rate of sulfur increased from 60% to 80%. Our customers are satisfied with our service.

Process Flow

Contact us:

|

|

Serena Fu |

Kira Zhang |

Teresa Zheng |

|

|

serena.fu@hot-mining.com |

kira.zhang@hot-mining.com |

teresa.zheng@hot-mining.com |

|

Skype |

Serena20140924 |

kira.zhangjing |

teresa.zheng1234 |