Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

XRT(X-ray Transmission) Intelligent Ore Sorter’s Application Ground and Underground

Ⅰ Technical Principle of XRT Intelligent Dry Separation Ore Sorter

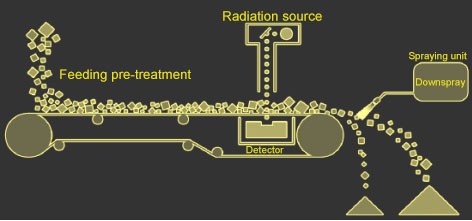

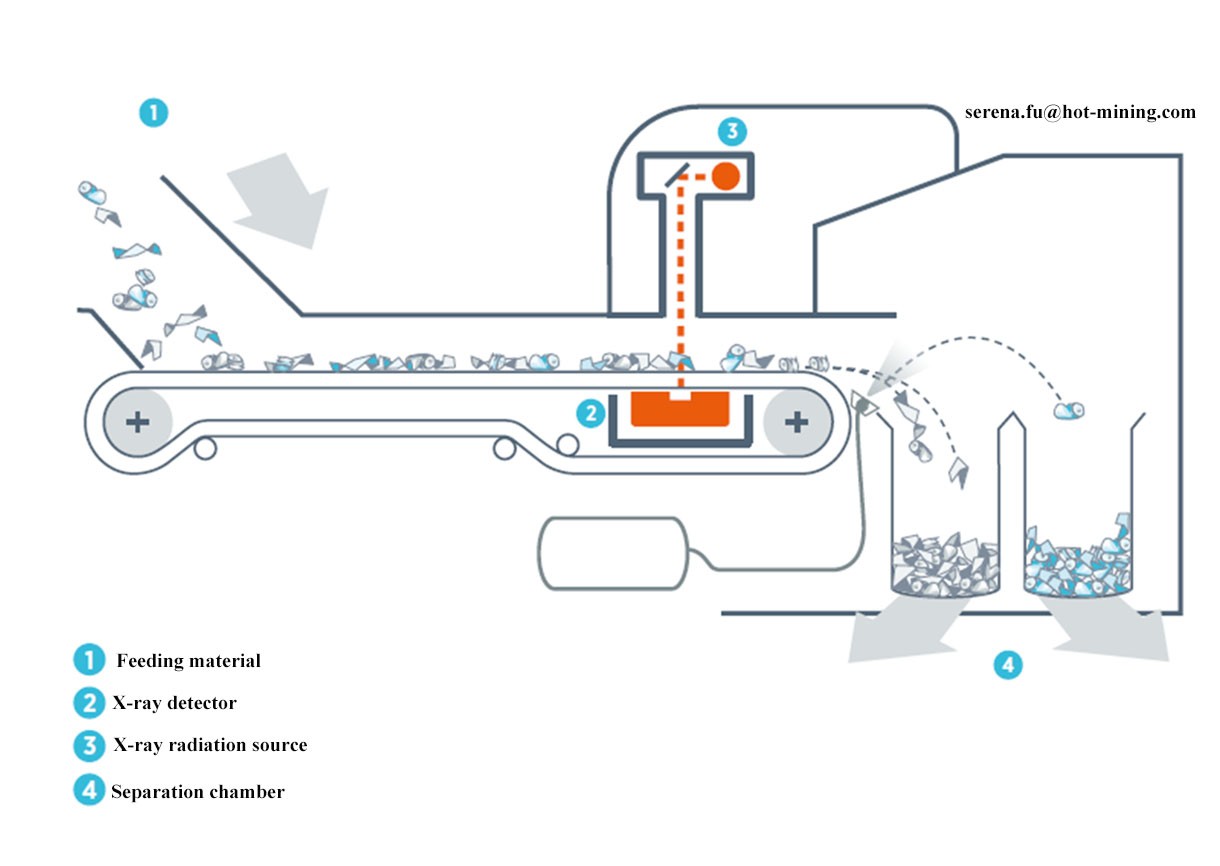

By using X-ray transmission technology and image recognition technology, and utilizing deep-learning algorithm technique, XRT ore sorter can recognize coal and gangue intelligently, which realizes accurate recognition and separation about lump coal. XRT intelligent ore sorter doesn’t need water and medium, it doesn’t produce coal slime, which means low processing cost and high lump coal yield.

Underground XRT intelligent dry separation ore sorter is researched and developed by HOT Mining, which is specially used for underground lump coal gangue pre-discarding, based on ground type ore sorter’s mature and successfully application. It can be effectively used to separate 300-50mm, 100-25mm lump coal and realize gangue pre-discarding, maximum feeding capacity can reach up to 380TPH per single unit, the “coal beating technique” can balance R.O.M de-impurity function. Gangue that is separated and discarded from underground lump raw coal can be taken as filling material for mining with filling technology, integrating coal mine mining, processing and filling and realizing GREEN MINING mission. The system’s machine-learning ability makes unattended operation possible, and it can replace traditional underground gangue pre-discarding methods like hand-pick, ROM-JIG and bath vessel.

Ⅱ Features of XRT Intelligent Dry Separation Ore Sorter

2.1 High separation precision

Percentage of gangue in coal and coal in gangue is both between 1-3%, the separation precision is almost same as bath vessel, and far better than ROM-JIG and other dry separation equipment.2.2 Wide separation size range

HOT Mining overcame technical difficulties which the X-ray cannot effectively separate lump coal>200mm, the valid upper limit reaches up to 300mm, lower limit is 25mm. We’re also researching and developing small-size XRT ore sorter whose valid lower limit is 10mm.2.3 Big feeding capacity

The maximum feeding capacity can be 380TPH.2.4 High intelligence

Intelligent control algorithm can realize auto-malfunction inspection.2.5 Perfect design

XRT intelligent ore sorter has got explosion-proof certificate and MA/KA certificate, as well as radiation-safety permit, dust-handling system is also included.

2.6 Safe and reliable

Crucial components are imported from first-level brand, which means high standard configuration.Ⅲ Application Field of XRT Intelligent Dry Separation Ore Sorter

3.1 Gangue Pre-discarding

- To replace hand-picking

- To replace ROM-JIG

3.2 Direct Production

3.2.1 No coal washing plant, it can realize 300-25mm lump coal separation for these conditions:- Coal mine without preparation plant

- Open-cut coal mine lump coal gangue discarding

- Stockpile gangue discarding

- Newly-constructed coal washing plant

- Bath vessel coal washing plant’s upgrade and capacity enlargement

- Reducing coal slime percentage in full size washing thermal coal washing plant

3.3 Other Applications

- Recover coal from gangue

- Coal and lignite separation in water-deficient area

- Other non-coal minerals separation(like kaolinite rock)

Ⅳ Three-Products XRT Intelligent Dry Separation Ore Sorter

Based on existing XRT intelligent ore sorter, HOT Mining researched and developed three-products intelligent dry separation ore sorter which can handle 200-50mm lump raw coal, it can separate coal concentrate, middlings and gangue in lump raw coal simultaneously. The principle is, by intelligent recognition of coal concentrate, middlings and gangue, three kinds of products can be separated after high-pressure air striking. The three-products XRT intelligent ore sorter can be applied for hard-separated coal in which much middlings are contained. It can realize coal product precise separation and processing, improving resources utilization rate and creating maximum benefit for clients.Ⅴ Underground XRT Intelligent Dry Separation Ore Sorter

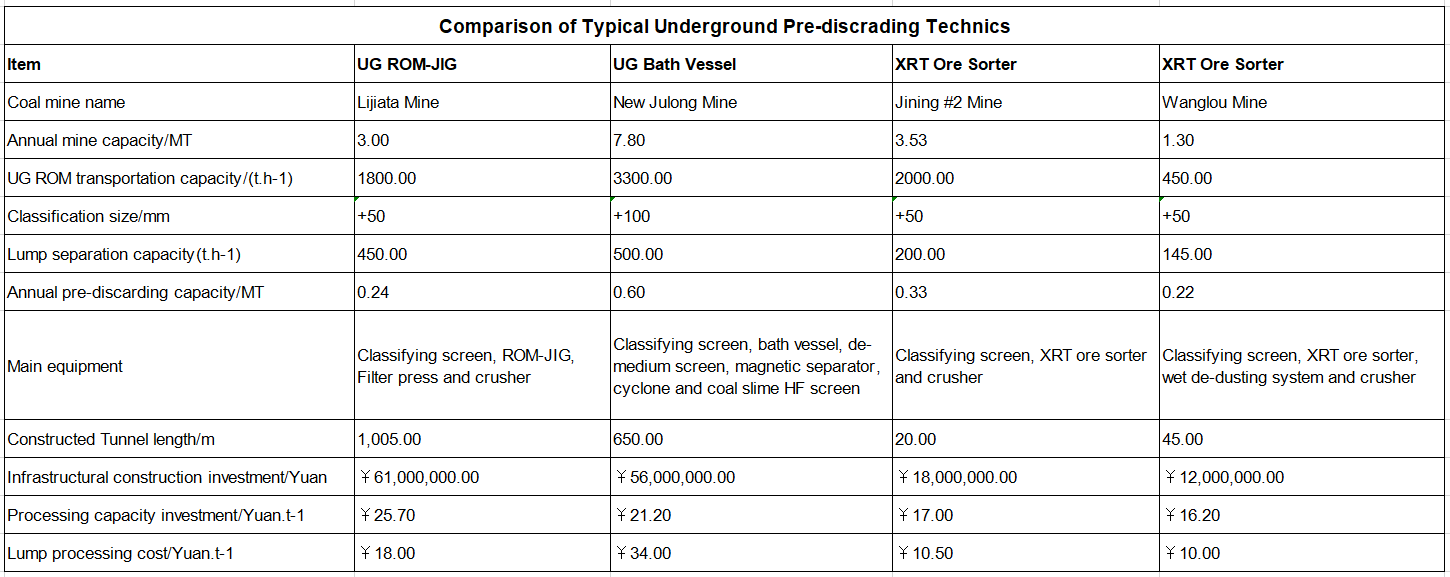

Compared with bath vessel, ROM-JIG and other traditional water washing techniques, XRT intelligent ore sorter needs no water and medium, also no slurry treatment. Thus XRT intelligent dry separation ore sorter has unique advantages when applied underground.

5.1 Concise and reliable system, unattended operation

Because of no dependency for water and medium, the process flow of XRT intelligent dry separation ore sorter doesn’t have sub-systems like de-watering, de-medium, water treatment and medium-recycling, thus the whole system is simplified and concise, little failure point and less failure rate, then realizing unattended operation.5.2 Small land-occupation, save investment

XRT intelligent dry separation ore sorter has small size and simple process system, the underground application could be integrated arranged in one panel.One coal mine in Shandong Province, China, the underground bath vessel system is arranged in a panel with 42m length, 6.8m width and 8.15m height, besides, another panel with 60m length, 5.66m width and 4.8m height is set for coal slurry sedimentation.

XRT intelligent ore sorter layout in underground coal mine in Shandong Province, China

From the comparison above we can see that, XRT intelligent ore sorter is better than bath vessel in underground application considering system configuration, equipment quantity, panel size and space occupation, thereby reduces investment.

5.3 Low OPEX

Underground XRT intelligent ore sorter has simple system, which can save labour cost; few equipment unit quantity, which means low spare parts consumption and maintenance cost; motor power of XRT intelligent ore sorter is smaller than bath vessel, which means less power consumption cost(only 1/4 of bath vessel), and no water cost and medium cost. Manufacturing cost of XRT intelligent ore sorter is lower than bath vessel system, operation cost is saved.

5.4 No medium and chemical agent consumption, no influence on existing auxiliary shaft

Bath vessel system needs consumable supplies like medium and chemical agent, these items need to be transported from auxiliary shaft, which takes up auxiliary shaft transportation capacity, it makes against production organization and coordination. Underground XRT intelligent ore sorter doesn’t needs water and medium, it doesn’t produce coal slurry, no need for medium and chemical agent, no occupation in auxiliary shaft.5.5 XRT intelligent ore sorter system is simple, which could be arranged separately in mining section

Underground ROM-JIG or bath vessel is usually arranged at coal stockpile, the discarded gangue needs to be transported long distance to working face for re-filling. It costs a lot for transportation. Underground XRT intelligent ore sorter can be arranged at mining section, the short gangue transportation distance reduces much cost.

Ⅵ Underground Application

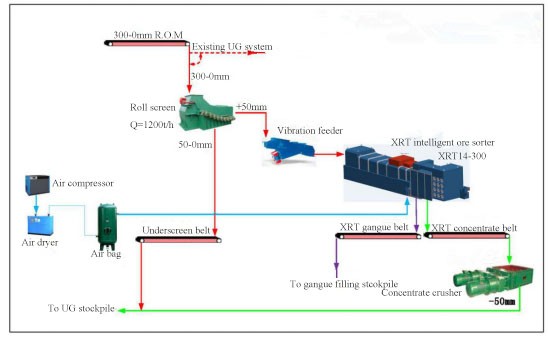

Wanglou coal mine, Shandong Province realized underground +50mm lump coal gangue pre-discarding by using XRT intelligent ore sorter.Model and capacity: 1 set of XRT14-300 type intelligent dry separation ore sorter, width of belt feeder B=1400mm, capacity 140TPH.

Expected performance: Working face R.O.M productivity can reach up to 2.6MTPA under the condition that main shaft hoisting capacity is 2.3MTPA, R.O.M quality transported in main shaft is improved a lot.

Underground XRT Intelligent Ore Sorter Gangue Pre-discarding Equipment Flowsheet

Ⅶ What Kind of Coal Mines Need Underground XRT Intelligent Ore Sorter?

7.1 The mines which don’t have sufficient hoisting ability, the production capacity is limited, however auxiliary shaft has surplus hoisting ability, by using XRT intelligent ore sorter to discard gangue underground, the gangue can be used for refilling or be hoisted by auxiliary shaft.For example, a coal mine in East China, the designed hoisting ability of main shaft is 0.6MTPA, among the R.O.M, about 7% is lump gangue whose size is >50mm, by using XRT intelligent ore sorter, 42,000.00 tons lump gangue is discarded underground per year, the main shaft released annual transportation capacity is 42,000.00 tons. 25,200.00 tons coal concentrate production can be increased if the coal concentrate yield is 60%.

7.2 The mines which has low coal seam, and heavy gangue content in R.O.M. By using XRT intelligent ore sorter, coal quality can be improved.

For example, a coal mine in West China, the main product is thermal coal, 2# coal seam is low coal seam, gangue content of R.O.M is huge, with low calorific. Because R.O.M from #2 coal seam is mixed with other coal seams, and are hoisted out together, the whole coal mine’s R.O.M calorific is low. In order to make whole coal mine’s coal quality meet standard, only partial of #2 coal seam can be mined, however it results in discontinuous mining face, and the production capacity of #2 coal seam can not be released effectively. By using underground XRT intelligent ore sorter to discard gangue of #2 coal seam, the gangue content in R.O.M is reduced, calorific is increased, #2 coal seam is released and utilized.7.3 The mines have filling system, but no separation system. By using XRT intelligent ore sorter to discard gangue, the separated gangue is used for filling.

For example, a coal mine in East China, the underground gangue refilling system is constructed, however the gangue for refilling needs to be transported from ground to filling working face, because of long gangue transportation distance, as well as energy waste from underground to ground, then to underground again. By combining XRT intelligent ore sorter with existing refilling system, repetitive transportation is avoided, thus realizing benign circle of partial gangue separated underground and refilling nearby.7.4 The mines which need to protect environment and has HSEC requirement

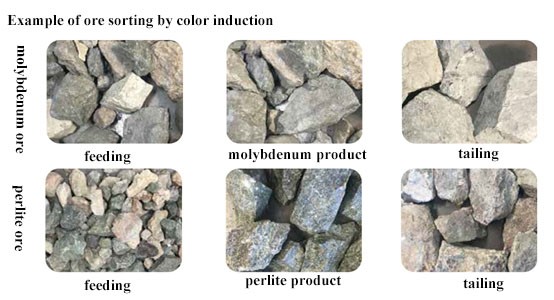

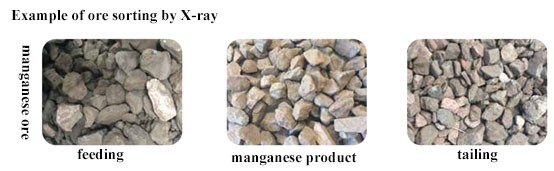

By using underground XRT intelligent ore sorter to refill working face with separated gangue, the transportation amount of filling material is reduced, coal gangue can be used for refilling nearby, thus to reduce coal mining’s impact on ground surface, and decrease farmland occupation and village relocation.Ⅷ Application in Non-coal Industry

If you want to know more information about it, please don't hesitate to contact us:

|

|

Tari Wang |

Kira Zhang |

|

|

tari.wang@hot-mining.com |

kira.zhang@hot-mining.com |

|

Tel/WA: |

+86 15927349651 |

+86 15281051932 |