Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

Test Analysis of Molybdenum Ore Sorting by X-ray Separator

X-ray in ore sorting

Since the X-ray was discovered by Roentgen in 1895, it has widely used in medicine, science, and technology now. The X-ray sorting machine used in the test is the HXS X-ray intelligent minerals separator, which is designed and manufactured by Beijing HOT Mining Tech Co., Ltd. It's suitable for the dry sorting process of ore and precious metals, ferrous metals, non-ferrous metals, and other types of ores and raw materials.

HXS X-ray intelligent minerals separator by HOT Mining

Ore Properties

The raw ore used in the experiment comes from a porphyry molybdenum deposit. Its’ main ore type is molybdenite. In the granite porphyry ore of the central part of the ore body, there’s a high content of molybdenite, with relatively uniform distribution and coarser particle size; in the edge of the ore body and low-grade ore, molybdenite has a relatively fine particle size and distributed unevenly.

Sampling

According to the basic characteristics of molybdenum ore, 18 tons of massive ore are sampled in this test. The selection ranges are from the waste rock (< 0.03%), low-grade ore to ore. The sampling range of original molybdenum ore grade is 0.01-0.1%.Experiment

Combining the actual situation of the open-pit mine and future production requirements, detailed tests were mainly conducted on three aspects as bellows:l. Particle size test: Analyze the particle size distribution of the open-pit mine boundary grade ore, and the proportion of lump ore suitable for the sorting machine;

2. Grade distribution test: By analyzing the Mo grade value of the raw ore, summarizing the Mo grade regularities of distribution in raw ore.

3. Compare the Mo grade value and proportion of the lump ore and the waste after sorting by HXS separator. And by comparing with the average Mo grade of raw material to analyze how much the average Mo grade has improved after sorting.

Test results and discussion

1. Test results

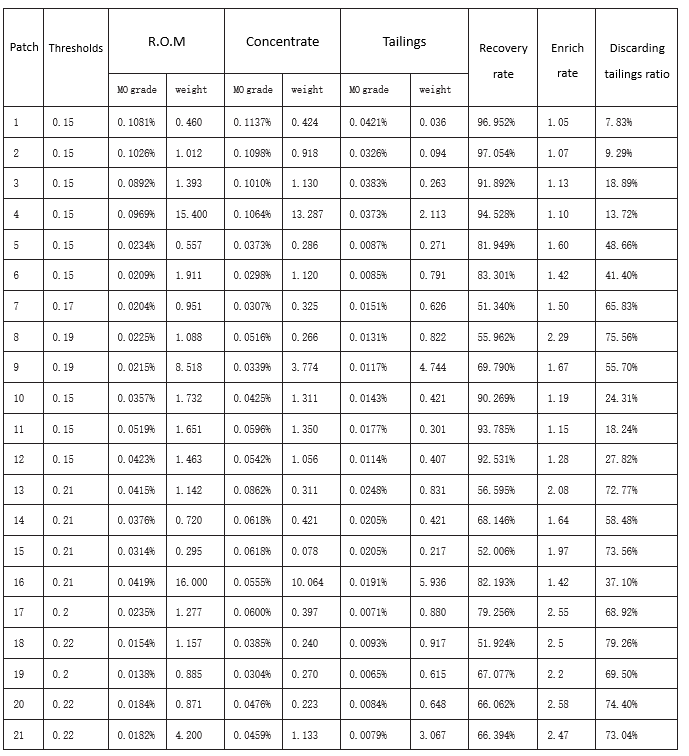

In the test, all the lump ore selected at each sampling point can be sorted, and the lump waste rock can be removed from the ore successfully. The MO grade in the tailings can be basically controlled at about 0.03%; after processing the waste by the sorting machine, the MO grade of the lump ore can be increased to more than 0.03%, and if we increase the threshold, the Mo grade of some lump ores can be increased to more than 0.05%. It can be clearly seen from the table below that with the increase of the threshold value, the grade of concentrate is obviously improved, the discarding tailings ratio is also significantly increased, and the enrichment ratio is also improved.

2. Application Significance

Analyzing the test data we can find that the X-ray sorting machine can sort the different grades of molybdenum ore at different locations. The X-ray sorter can effectively separate the boundary lump molybdenum ore of the mine and can remove the waste rock to improve the quality of the molybdenum ore raw materials, or it can sort the concentrate from the low-grade lump ore and waste, which provides processing plant with lump concentrate with higher quality, increases the mine's "lifespan", that is, the service time of a mine. The separator maximizes the recycling of resources and has a certain significance for the sustainable development of the mine.However, the grade of concentrate and tailings, the enrichment ratio, the recovery ratio, and the tailing ratio of the lump ore processed by the sorting machine are affected by the nature of the original ore, and not all are determined by the performance and threshold of the X-ray sorting machine.

Therefore, the optimal thresholds that suitable for the application mines should be adjusted in accordance with the nature of the ore and the current economic situation to achieve better returns.

-----------------

Contact us:

Teresa Zheng

Email:teres.zheng@hot-mining.com

Tel/WA: +86 15281626323

Tiffany Chen

Email:tiffany@miningmes.com

Tel/WA:+86 18282103350

Tari Wang

Email: tari.wang@hot-mining.com

Tel/WA:+86 15927349651