Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

Know-How? Application of XRT- Intelligent Sorting System in Mineral Separation

At present, China's coal mainly uses wet separation process, but China's water resources are scarce, and most of the coal is distributed in arid and water shortage areas such as northwest.The traditional wet separation process consumes a large amount of water, and because the product takes away part of the water, it will also reduce the calorific value of the product. At the same time, it will increase the amount of slime for the easily slime coal, reducing the overall benefit of the coal preparation plant. Therefore, it is urgent to replace the wet coal preparation process with the high-efficiency dry coal preparation technology to realize clean utilization of coal, save water resources and reduce environmental pollution.

1. Traditional Coal Block Separation Process

1.1 Heavy Medium Shallow Slot Sorter

The heavy medium shallow groove separator is to separate coal according to the floating and sinking principle. the upper limit of the separation particle size range can reach 300 mm, the lower limit is 6 mm, the separation particle size range is wide and the separation accuracy is high, but the separation process needs to use medium, the medium system is complex, and the instability of the medium system will affect the separation effect.1.2 Movable-sieve Jig

The dynamic sieve jig is used for sorting with water as the medium, which is generally used for 300~50(25) mm block coal to discharge gangue in advance instead of manual hand selection. The dynamic sieve jig has the advantages of simple process and less water consumption, but the separation accuracy is low, the equipment is large, the structure is complex, and the cost of investment and maintenance is high.1.3 Dry process sorting

At present, the more mature composite dry coal preparation technology with air and pulverized coal as medium, with air flow and mechanical vibration action power, make the material loose on the bed surface, and realize sorting by density. The separation granularity range is 8~80 mm, the separation does not need water, the technology is simple, suitable for coal gangue discharge and dry water shortage area coal preparation. However, the process can not separate blocks of coal more than 80 mm, the separation accuracy is poor, the coal content of gangue is high, the energy consumption is large, and it is greatly affected by the external moisture of raw coal.2. XRT- Intelligent Separation

To solve the problems existing in several kinds of block coal sorting technologies, Beijing HOT Mining Tech Co., Ltd, based on sensor technology and X ray transmission technology, XRT intelligent mineral ore dry separator a new solution for mineral ore sorting to remove waste and coal. sorting system uses our unique AI computer algorithm to identify the internal physical features of extracted materials, and sorting coal and gangue through high pressure blower according to customer requirements.

2.1 Main Structure

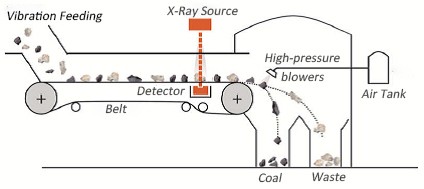

Feeding system:The belt conveyor is used to make the ore stably enter the scanning area to ensure the accuracy of detection and separation.Detecting system:An X-ray source is installed on the top of the system and, after the ray irradiates the ore, the detector receives the X-ray signal and converts & collects it. Then uploads it to the data processing system.

Data Processing system:Using the AI algorithm to analyze the ore image and data, achieving the recognition of the ore and waste. At the same time, it is decided whether the target ore (waste) needs to be removed by blowing.

Executing system:The target ore is ejected away from the original route by the power of the high-pressure pneumatic blowers to achieve the purpose of separation.

2.2 Working Principle

The equipment uses X-ray to scan the raw ore, collects data from the detector, and distinguishes the ore and waste rock through intelligent algorithm, and blow the waste rock away with the High-pressure blowers.

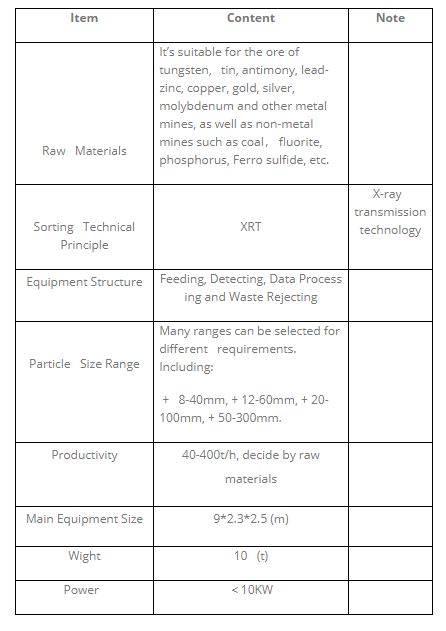

2.3 Technical Parameters

2.4 XRT Separator: Improve your Productivity

1.Wide range of particle size, including + 8-40mm, + 12-60mm, + 20-100mm, + 50-300mm.2.The space of air blowers can be selected flexibly (7mm, 10 mm, 12.5mm) according to the requirements of ore processing capacity and the size of ore particles.

3.Among the range of + 12-60mm grain size, the average output can reach about 60-100tph; for + 20-100mm, the output is more than 120t / h. When processing large grain size coal mines, the output is as high as 400t / h.

4.The data processing system adopts high integration AI algorithm to achieve millisecond operation rate and high processing capacity of ore dressing recognition rate. Which can increase ore recognition ability and accuracy, improve ore separation accuracy and make the separator is suitable for many kinds of ores.

5.Safe operation and maintaining cost.

6.It takes replace of hand sorting in some certains with higher efficiency.

2.5 Application of XRT Intelligent Preparation

(1) Coal preparation plant in advance: discard some gangue in advance, reduce the downstream process processing costs(2) Separation of coal and gangue in arid and cold areas

(3)Replacement of hand-selected gangue link: reducing mis-selection and improving efficiency

(4) Replacing jig: It solves the problems of poor sorting accuracy, high investment of equipment and heavy maintenance work

(5) In order to ensure the quality of raw coal and reduce the cost of production on the ground, coal is discharged in advance

(6)The sorting machine has been successfully used in tungsten, tin, antimony, lead-zinc, copper, gold, silver, molybdenum and other metal mines, as well as non-metal mines such as coal, fluorite, phosphorus, Ferro sulfide, etc. Our sorting machine is currently the only X-ray intelligent sorting machine with mature application cases in non-ferrous metal ore, ferrous metal ore, non-metallic ore, coal mine and other fields.

2.6 Application Cases

2.6.1 Project background

SX antimony industry co., ltd. is a formal mining in 1897, set antimony mining, selection, refining, scientific research as one of the large non-ferrous metal joint enterprises. After more than 120 years of mining, antimony ore grade decline. Tailings reservoir full capacity, waste tailings no place to discharge. As one of the three key technologies in 2018," X ray intelligent pre-selection tail "was involved in a project.

2.6.2 Case performance

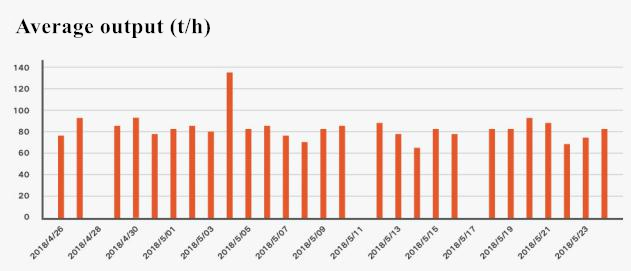

Installation time: April 2018Homework graded:-100+15mm

Output :90~120 t/h

Drop-off rate :60%~80%, based on ore adaptation

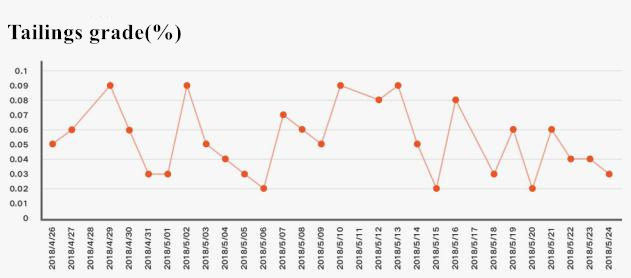

Antimony content in waste rock from original selective production line:0.35%

XNDT-104 intelligent separation of tailing antimony content

Alternative manual workers :104

Value creation: approximately 20 million per year

3. Conclusion

As an efficient and low-consumption, energy-saving and environmental-friendly sorting technology, XRT intelligent sorting machine gangue removal system has been developed with the advantage of no water and no medium. I believe that XRT intelligent sorting system will have a very broad prospect in the domestic application of gangue discharge, and make due contribution to China's mineral processing industry.

Any more information, can contact us:

Aria Yang

Email: aria.yang@hot-mining.com

Tel/WA:+86 13185581224(Whatsapp)

Tari Wang

Email: tari.wang@hot-mining.com

Tel/WA:+86 15927349651

Kira Zhang

Email: kira.zhang@hot-mining.com

Tel/WA:+86 15281051932