Why H-TBS? (Teetered Bed Separator, or Hydrosizer)

Successful worldwide application of TBS

The world's major coal producing countries such as Australia, China, Mongolia (Energy Resources LLC applied H-TBS in UHG CHPP), Russia and the United States have verified the broad adaptabilities of TBS. The fact that the performance of TBS coarse slime separation far exceeds those of other similar products. It has become the first choice of coarse slime separation.

The technical advantages and adaptabilities of TBS – Compared with Spiral Separator Spiral

EP value

The EP(guaranteed value of TBS is 0.12/, and under normal circumstances it is about 0.08.The minimum EP value of TBS can reach 0.038, which makes heavy-media separation possible by TBS, while the EP value of the spiral separator is 0.2.

Separation density control

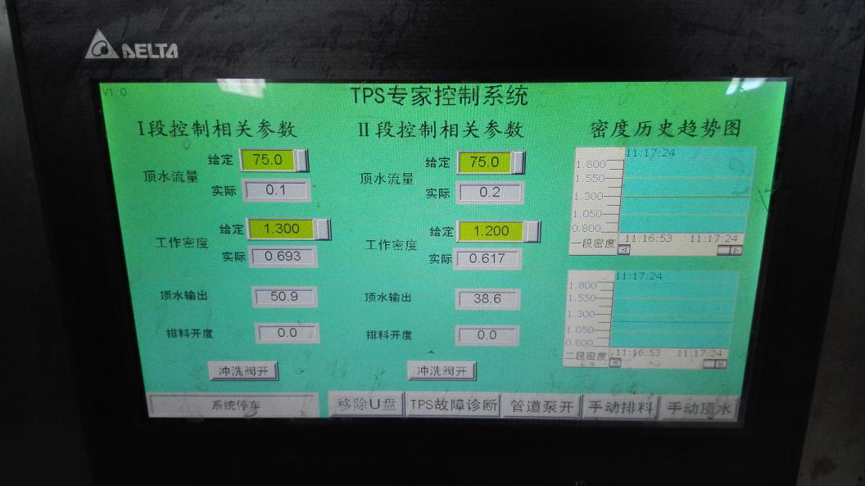

TBS have a density control system to ensure the accuracy of density separation, separation density can be adjusted to different degrees so as to adapt to the feed quality variation. The separation densities range from 1.4 to 1.9. In the separation density range, the fine coal ash remains stable. Fine coal ash can be easily achieved using TBS which controls separation density automatically.

Spiral Separator does not have a density control system, which means it can’t control the separation density automatically. The separation density of Spiral Separator ranges from1.6 to 1.9,, which makes it almost impossible to separate low ash fine coal.

Separation Efficiency

In separating fine coal with the same amount of ash, the fine coal recovery of TBS is higher than the spiral separator. Under the same separation density, the amount of ash in separating fine coal using TBS is lower than that using the spiral separator.

The worldwide preparation plants have confirmed the fact that in coarse slime separation, the interference bed separator sorting is better than the spiral separator, which makes it reasonable to say that the interference separator is the best choice for coarse slime separation.

The other equipment, such as: spiral separator, are applied as TBS auxiliary equipment gradually while TBS has become the first choice.

Commissioning training and technical support

Experienced engineering team: The preparation engineers and TBS equipment engineers of HOT has any successful experiences, which means they can provide the ore suitable and practical support for preparation plants.

Perfect training system

Providing a wealth of related documents similar experiences sharing, coal preparation site training, and the specific training programs tailored for customers is our pleasure.

Technical support

Normally, after the TBS commissioning and technical training by our engineers, technical support is almost unnecessary because of the high-level automatic operation and centralized control regulation of TBS. If technical support is urgently needed, remote video guidance can be provided immediately.(The data access should be available for HOT temporarily or remote video guidance can be provided by communication tools like Skype.)

For emergency support, HOT can provide remote assistance (Coal temporary need for HOT open data access, or remote video guidance through Skype and other tools).

The actual production data report of TBS

Please refer to Annex "Tianyuan coal preparation plant TBS-3.6 -- April Report 2015-5"

This is a one-month running record of Coking Coal Preparation Plant (main production data, equipment performance, product indexes) for reference.

Prerequisite:

(1) The amount of washing ash using TBS can be as high as 40% to 50%.

(2) This coal preparation assesses the coal gangue index mainly.(The TBS technical parameters can be adjusted according to the actual needs of the preparation plant.)

(3) The diameter of this type of TBS which has four discharge systems is 3.65m.

Brand-new H-TBS Product, the Three-Product Teetered Bed Separator

Three-product teetered bed separator, labeling as T-TBS, as an upgraded device, is emerging to get rid of an awkward facts thoroughly that traditional TBS could only produce two products, overflow and underflow. This paper introduces the structure characteristics of T-TBS with type I and type II, and its four possible applications. On a basis of actual separation performance, it’s demonstrated that two-stage separation is necessary when treating coal slime. The float-sink analysis shows that TPS has the similar separation performance as heavy medium cyclone when treating easy-to-clean coal with -1.0 mm size. Combining the washability of the feed, when clean coal with ash 8.56 % is produced, theoretical separation density is about 1.95 g/cm3 and theoretical recovery is 85 % from washability curve while actual recovery is 82.54 % and separation efficiency goes to 97.11 %. The disadvantage of traditional TBS could be exaggerated when treating difficult-to-clean coal due to only producing two products. The birth of TPS provides a better way of solving the problem.

Application status of traditional TBS

Traditional teetered bed separator (TBS) is one major device of dealing with coarse slime nowadays, with a great appreciation of only circulating water used as power source without other medium, low investment, low operating cost, perfect automation control and easy layout.

Coal slime could be only separated into two products at a time using traditional TBS; when to-be-treated material contains more than 20% middle density fraction, the separation performance gets lower with high clean coal loss in underflow. These mentioned disadvantages limited the application of TBS[5]. Meanwhile, due to effect of equal settling particles, when the feed has wide size fraction, mineral particle with high density and small size goes into overflow, which leads to stringent requirements of the following dewatering; sometimes it will determines the total separation performance of coarse slime separation.

Even so, TBS is still irreplaceable nowadays due to its advantages and has widely used to tackle raw coal slime, magnetic separation tailings, slime of jig clean coal and so on. The main advantages could be concluded into the following two aspects,

1) With the use of TBS, the flowsheet of “first classifying by size and then separating by density” is achieved to reduce the effect of size on the density-based separation to maximum extent, thus improving the total separation efficiency of whole size material. The flowsheet that the whole size raw coal without classification is separated using jig or heavy medium separation technique accounts for most in coal preparation plant in China before 2008[7]. Except some plants with high quality coal, under normal circumstance, slime of jig clean coal or magnetic separation tailings of clean coal has more ash content than total clean coal, average 2%, in worse case as high as 10%[2], which is called “carrying ash” phenomena. Reconstruction of these preparation plants with original technique is usually carried out with the use of TBS, or slime of jig clean coal and magnetic separation tailings is separated again using TBS, removing +1.6 kg/l fraction and eliminating “carrying ash” phenomena, thus improving clean coal quality and total benefit. In another case, pre-desliming of raw coal before separation is performed to achieve jig separation or heavy medium separation without coal slime. No matter which form is adapted, coarse slime separation is carried out by itself.

2) The flowsheet of desliming of raw coal + TBS separation of raw coarse slime+ heavy medium separation has been widely used in a lot of new-built separation plants. Comparing with original flowsheet, the new one has a great appreciation due to high magnetic material content and low viscosity in qualified medium, low separation size and obvious low medium loss with the same equipment of recycling medium.

Introduction of three-product TBS

The parameters affecting separation performance of TBS could be summarized into four aspects, that’s, washability of coal, size range of feed, dewatering and desliming performance of the following procedures and performance of the device. Due to its intrinsic property of producing two products, when treating +1mm material with all the same four parameters above, TBS has lower separation efficiency than heavy medium cyclone, with the least probable error value (Ep) 0.071. Therefore, it’s important to develop coarse slime separator which utilizes all kinds of advantages and produces three or more products, leading to the perfection of the “irreplaceable technology at present” to maximum extent. Under the circumstance, three-product teetered bed separator comes into being.

Three-product or more-product teetered bed separator, developed on a basis of traditional TBS technology, is authorized to be manufactured by national invention patent with complete intellectual property, and is also called three products separator, labeling as TPS.

Two kinds of TPS were invented, type I and type II.

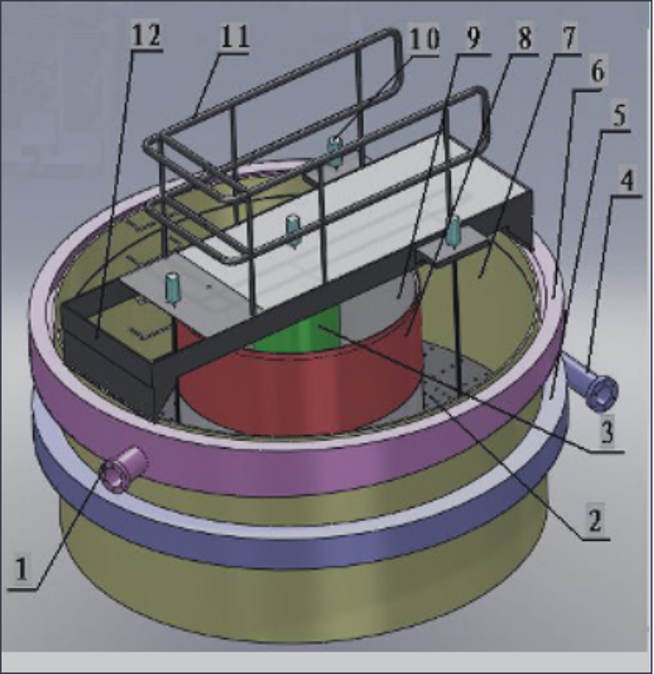

TPS with type I is comprised of two or more barrels with the same central axis. Taking two barrels as an example, it’s named inner barrel used for first stage of

separation and outer barrel used for second stage. Feed goes into inner barrel via feed well, and the first upwards water is moving from the bottom of inner barrel, thus producing the first teetered bed layer with material from feed well. High density particle settles through the first teetered bed layer and discharged from the outlet at the bottom of inner barrel as product (1), and the light particle goes upwards into the outer barrel. Meanwhile, the second upwards water is going up from the bottom of outer barrel and mixing with the particles in overflow of inner barrel and forming the second teetered bed layer. The heavy particle sinks and discharges from the outlet of outer barrel as product (2), and the light particle goes up and concentrates as product (3). After separation of first stage and second stage, three products are obtained, that’s, underflow of first stage, underflow of second stage and overflow of second stage, which is illustrated as Figure 1.

Notes: 1. Overflow tube; 2. Water spray nozzle; 3. Feed well; 4. Outer water feeding tube; 5. Outer water feeding circular belt; 6. Overflow box; 7. Outer barrel; 8. Guide barrel; 9. Inner barrel; 10. Discharge actuator; 11. Handrail; 12 Platform;

Figure 1 Structure diagram of TPS with type I

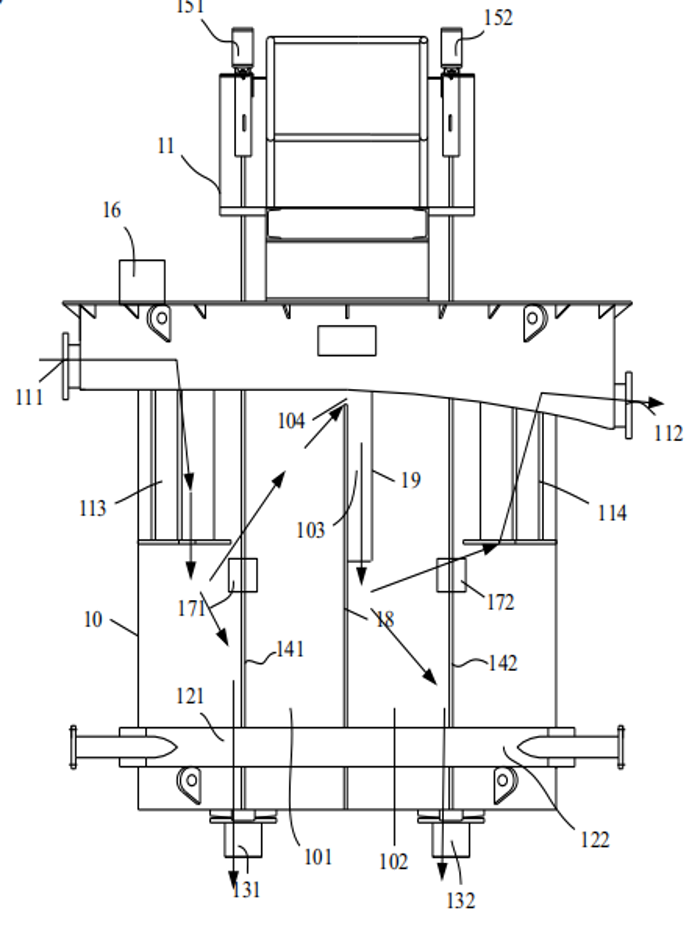

Figure 2 structure diagram of TPS with type II

More information about TPS contact us:

Kira Zhang, International Business Manager

Email: kira.zhang@hot-mining.com

Tel/WA:+86 15281051932

Teresa Zheng, International Business Manager

Email: teresa.zheng@hot-mining.com

Tel/WA:+86 15281626323