Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

Technology Share for Underground Loader Remote Control System Used in Metal Mine

Due to the danger of car crash caused by the roof falling from the manual operation of underground loader in the underground mine, Alpha modified one set of Anchises 2m³ loader in Chongli Zijin Mining in Hebei in October 2014. The diesel underground loader is equipped with a remote control mode based on the original traditional manual operation mode.

After 8 days of upgrading and commissioning, the wireless remote control operation of the Underground loader was realized, which not only retained the original manual operation function of the loader, but also added a set of wireless remote control functions? Operators can leave the cockpit for easy operation of loader within 50 meters, the operation is simple, the movement is flexible and light. So far, we have successfully upgraded two remote underground loaders for the Chongli Zijin project department. The upgraded remote control loader has been tested through manual and remote control both on ground and underground, all functions are normal, and the system runs stably. The underground use effect is remarkable, especially in the underground goaf, which not only ensures the personal safety in the mining process of the goaf, but also greatly improves the mining rate of the goaf, reduces the ore loss and saves mineral resources.

Clients equipment maintenance personnel participated in the remote control upgrading process throughout the whole process. After communicating with Alpha technicians, they learned that most of the control functions of the Anchises 2m³ underground loader are manual mechanical control, instead of the current popular hydraulic pilot control mode, this design makes the remote control upgrading very difficult. It needs to modify the gearbox, steering system, working main valve, brake system and throttle system of the loader, and then add the Alpha's independent research and development product-AL211 underground loader wireless remote control system, the program has a great change to the original loader, the entire upgrading and commissioning process lasted 8 days, the following will introduce the whole process for everyone to learn reference.

1. Gearbox Modification

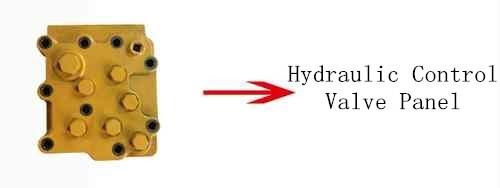

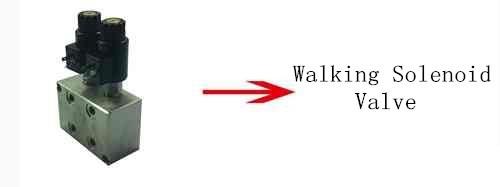

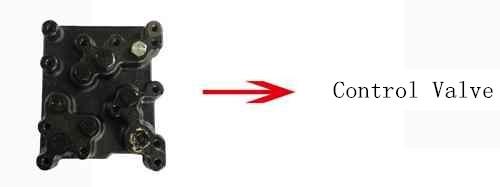

The original DANA's original loader gearbox is 6 gears, fully manual control, and after upgrading, both manual and remote control mode are realized. First, remove the operating valve panel on the gearbox and install it with the hydraulic control valve panel to the original position; then combine the operating valve panel and the control valve to form a manual control unit, and add a solenoid valve between the two panels as remote control unit.

2. The Steering System Modification

The original steering system is mechanically controlled by the operating lever of the cab. After the original steering valve is modified, it is replaced by a pilot hydraulic steering valve. The pilot oil circuit is routed by a 2-way pilot valve and a set of 2-way solenoid valves. The pilot valve has a joystick for manual control and a solenoid valve for remote control.

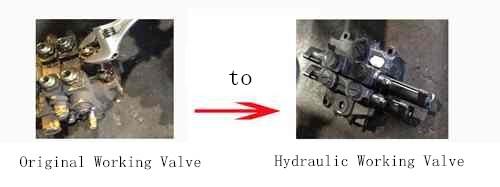

3. The Working System Modification

The original loader working valve is mechanically controlled and replaced with a pilot hydraulic control valve. With the steering system, a 4-way pilot valve and a set of 4-way battery valves are added to form the pilot oil circuit. The pilot valve is manually controlled, and the solenoid valve realizes the remote control function.

4. The Brake System Modification

Parking brake system: hand brake, which is by electro-hydraulic control, hydraulic release, spring brake; Only the electrical system is modified, adding the remote control function;

Working brake system: foot brake, which is by hydraulic control, hydraulic brake, spring release; 2 sets of brake solenoid valves are added to achieve remote control brake.

5. The Throttle System Modification

The throttle driving cylinder and the pedal used in the original loader realize the throttle control, in order to better realize the proportional control function of the throttle; the electronic throttle control is used. The electronic throttle pedal is used for manual control; the PWM module is used for remote control; Replace the original loader throttle driving system with throttle-executor;

6. The Electric Control System Modification

The original loader control box was modified to increase engine start, engine flameout, headlights, and rear lights.

7. Loader Remote Control System Site Commissioning

After testing, the modified remote-controlled underground loader can be freely switched between manual control and remote control according to actual needs. The system runs stably and operates flexibly. The proportional operation and real operation of the remote control handle are almost the same, and have various safety control strategy ensures that the loader leads to the safe side in any state.

Alpha has rich experience on loader remote control system modification; we can add remote control system for any model of underground loader.

If interested, just contact us:

E-mail: kyle.lee@alpha-technology.com.au

Tel/WhatsApp(Skype):+86 15756875803

Web: www.alpha-technology.com.au