Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

The World’s First IIoT-Applied Intelligent Coarse Coal Centrifuge

HOT Mining has launched the world’s first IIoT (Industrial IoT) applied horizontal vibrating coarse coal dewatering centrifuge in Feb. 2019.

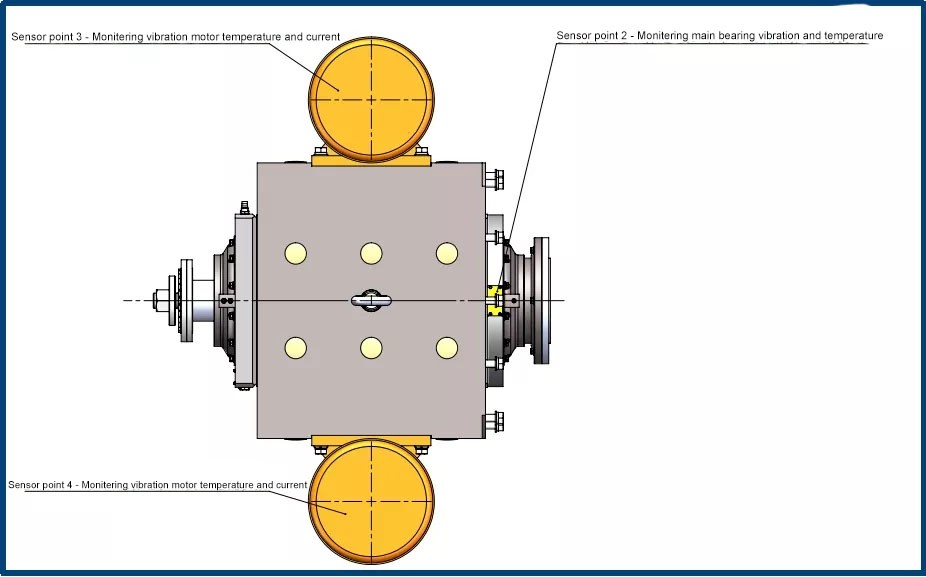

The new THC series vibrating coarse coal centrifuge utilize the latest technology available for coarse coal dewatering applications and yet are both simple and cost effective to maintain, the five models (1100, 1200, 1300, 1400, 1500, 1650) are the world's first IIoT-applied horizontal vibrating coarse coal dewatering centrifuge designed around proven principles, such as basket angle, G-force. This ensures maximum throughput with highest dewatering efficiency at minimal operating costs.It’s expertly designed to deliver stable performance and availability in the most arduous coal dewatering applications.

Key Parameters of THC Series Centrifuge

Capacity: 140t/h~410t/h

Feeding Particle Size: 0.5~50mm

Feeding Moisture: 18%~25%

Product Surface Moisture: 5%~9% (Depends on material size distribution)

How IIoT is Making Centrifuges More Efficient and SMARTER?

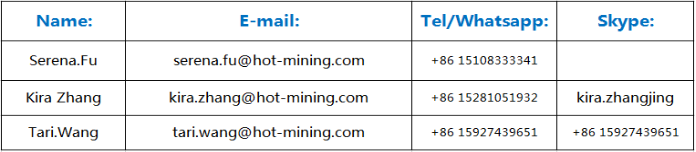

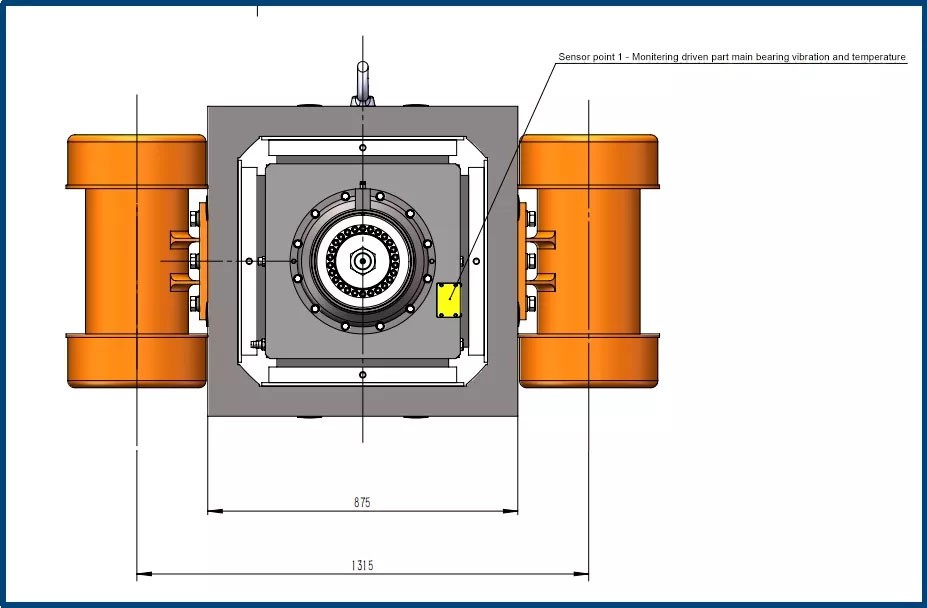

① Predictive Maintenance - intelligentize centrifuge operation and maintenace management

To ensure centrifuge stable and long-term operation, the creative equipment health intelligent monitering system can supervise running status of crucial components in real time, thus to prolong the working life of centrifuge.

Monitering crucial components’ operation parameters like temperature, current and vibration by sensors, and upload to cloud to conduct intelligent analysis, predicting centrifuge operation failure by special AI arithmetic and prevent break down, then ensure continuous production.

② Moniter Solid Particles Content - analyze and predict basket abrasion

By monitering and investigating solid particles content in centrifugate, foreseeing and analyzing abrasion status of sieve basket in advance, thus to be convenient to change wear-resistance parts, reduce abnormal breakdown, finally to guarantee dewatering effect of centrifuge.What’s more, the operation data can be viewed at PC and wechat in real time, also the warning message will be pushed to maintenance personnel the first time.

The Unique Advantage Compare With Similar Centrifuges

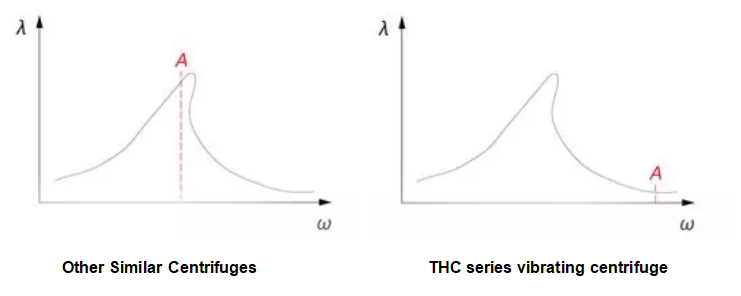

Compared with ordinary centrifuge, THC series horizontal vibrating coarse coal centrifuge adopts independently operating double vibrating motor, the operating frequency is higher than natural vibrating frequency, which has better adaptability, and not sensible to feeding change, with stable amplitude.

Compared with ordinary centrifuge, THC series horizontal vibrating coarse coal centrifuge adopts independently operating double vibrating motor, the operating frequency is higher than natural vibrating frequency, which has better adaptability, and not sensible to feeding change, with stable amplitude.

- 1. The key parts are from world-famous brand, performance well and component wear resistance.

- 2. Two individual vibration motor are adopted, high exciting force and effective.,The amplitude is 2~6mm, and could be adjusted expediently.

- 3. The adoption of PP bumper block and shock-absorbent rubber sheet, reduce the noise and vibration of base.

- 4. The integrated design ensures the uniformity and looseness of the incoming material by means of material vibration during feeding.

- 5. The rotary parts adopt the pressurized lubrication system with thin oil system, which combine three functions: lubrication, cooling and lubricating oil purification.

- 6. All wear parts are protected by polyurethane or high alumina ceramic lining, which prolongs the service life of the equipment.

- 7. Realize intelligent control of mechanical & electrical integration of equipment, on-line monitoring of bearing temperature, early warning, improving the reliability of equipment operation.

- 8. Motor position and opening direction can be flexibly selected with users.

-

- Now the first 3 sets have been installed in a coal preparation plant in China.

No matter to build new coal washing plant or upgrade, it’s better to have an experienced engineering company like HOT Mining.

CONTACT US: