Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

Introduction of CIL process

1. Application of CIL Process

CIL is developed based on all-slime cyaniding followed by Zinc replacement, including thickening before leaching, leaching and adsorption, desorption of gold-loaded carbon and electrode-position, acid-washing and thermal regeneration , gold metallurgy. The most outstanding feature of CIL process is that leaching and absorption are simultaneous, in this way can save the agitation tank and the investment. It is widely used in the newly built leaching plants recent years.

CIL process is suitable for the treatment of oxidized gold ore with low sulfur content and mud content. It is unsuitable for the gold ore with high grade silver. Generally, the proportion of gold and silver should not exceed 1:5. The best conditions for CIL process in China: PH=10-11, sodium cyanide concentration is not less than 0.015%, the particle size of activated carbon is 1.0-3.35mm, the type of carbon is coconut shell activated carbon, and the slurry concentration is 40-45%.

2. The Preparation Before Leaching

Before leaching, beside crushing, grinding and classification,some operations such as debris-cleaning,slurry thickening and the addition of detergent are also needed.

2.1 Debris-removal Operation

Sawdust, grass roots and other debris in the slurry can easily cause clogging of the pipe and screen, and the sawdust will absorb gold, so it must be removed before leaching. In general, two times of debris-removal operations are necessary in grinding process, respectively, in the first and the second stage grinding classification overflow. Intermediate frequency linear vibrating screens are widely used as debris-removal equipment, in the first debris-removal operation, spiral screen and drum screen are also can been seen, debris-removal sieve size should be as small as possible,but must ensure the slurry can flow through the sieve easily.

2.2 Thickening Operation

The grinding overflow fineness of normal gold ore is 85-95% smaller than 0.074mm, grinding overflow fineness of flotation concentrate is up to 99% smaller than 0.047mm. The overflow concentration is just 18-22%, which is not suitable for direct leaching, so thickening is required.

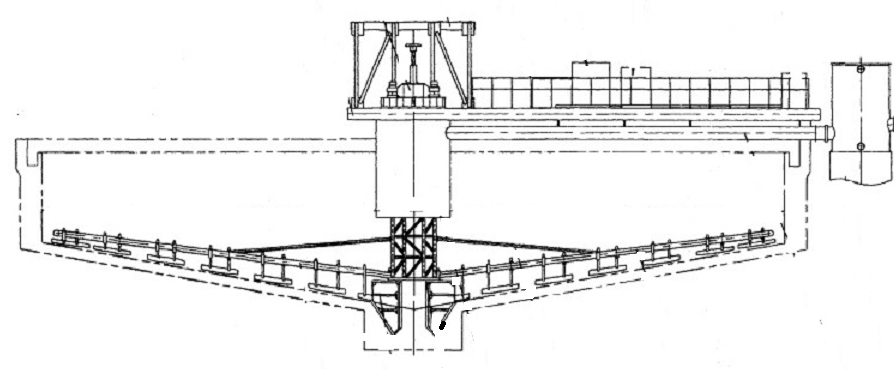

High efficiency thickener is widely used because of its small footprint and high operation efficiency.

3. Leaching and Absorption

Leaching and absorption are simultaneous is the most outstanding feature of CIL process. Its segment number is generally 6-10, as the sodium cyanide is added in the first tank, and little gold is leached, most CIL plant will add the activated carbon from the second tank to the last one. Carbon segregation screen is arranged in every absorption tank to separate the carbon and slurry. Slurry flow automatically from the first tank to the last one while the activated carbon flow reversely. It means that the activated carbon is put into the slurry at the last absorption tank and gold-loaded activated carbon is taken out at the first absorption tank. After screening and washing, the gold-loaded activated carbon will be sent to the desorption operation. After absorption, the gold grade in the tailing solution will be 0.01-0.03g/m³.

3.1 Leaching

During the leaching, sodium cyanide will react with gold and silver, and produce cyanide complex with gold and silver. Lime is used for keeping the PH, so as to prevent the production of toxic gas HCN. In the high standard automation CIL plant, a HCN gas detector is always installed in the leaching and absorption area.

The Main Parameters of Leaching

|

Grinding Overflow Fineness |

85-95% smaller than 0.074mm |

|

Slurry Concentration |

40-45% |

|

Sodium Cyanide Concentration |

Not lower than 0.015% |

|

PH Value |

10-11 |

|

Aeration Amount per m³ Slurry |

0.002-0.003m³/min |

|

Segment Number |

6-10 |

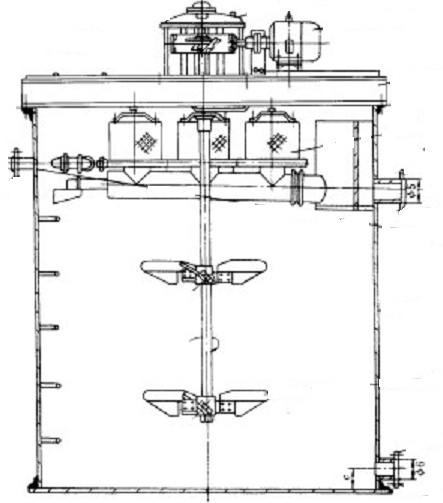

Oxygen is required for the reaction of the sodium cyanide with gold and silver. In theory, 0.4g oxygen is need to react one gram gold, however, in practice the amount is much large, due to that gold ore always has various metal sulfides, which will also consume oxygen to react with sodium cyanide. In actual production, the medium pressure air of 100KPa is used to pass through the hollow shaft of the agitator. Air flow is generally controlled and measured by a rotor flow-meter.

In recent years, the two key technical and economic index that strengthen leaching and reduce the consumption of cyanide are paid attention by engineers and experts, CILO process starts to come into view. CILO process has these advantages as below:

(1) Accelerating leaching kinetics, reducing leaching time, and sometimes increasing leaching rate of gold and silver;

(2) Reducing consumption of sodium cyanide;

(3) Better leaching result in very fine gold ore than CIL process;

(4) Effective leaching of ores containing higher oxygen consuming minerals;

For example, one gold mine in Hebei province, undated the CIL process to CILO process. They did not change any equipment only increased an oxygen compressor unit to replace the original air compressor. The leaching time was shortened from 36-42h to just about 20h, and the leaching rate was also increased by 0.89%, the consumption of sodium cyanide was also saved 0.27g per ton. Due to the shortening of leaching time, the production capacity of the original leaching equipment has increased from 300t/d to 643t/d, which has created obvious economic benefits.

Hydrogen peroxide or hydrogen peroxide replacing the compressed air can achieve the purpose of CILO, but the specific effect needs to be determined by test and simulated production experiment.

3.2 Absorption

Commonly used activated carbon is coconut shell activated carbon, it has better adsorption performance and abrasion resistance. Carbon segregation screen should be installed in the exit of each absorption tank, and the screen mesh generally choose 24 mesh 304 stainless steel screen.

The general shape of the carbon segregation screen is round and V, liner vibrating sieve and other form screen can also be seen in some CIL plant.

3.2.1 Main Factors Affecting the Adsorption of Activated Carbon

The main factors affecting the adsorption of activated carbon contains the adsorption capacity, strength, particle size of the activated carbon.

After long distance transportation, there are a lot of broken carbon or powdered carbon, which need to be pre-treated before use to exclude its influence.

3.2.2 Influence of Slurry Properties

The main influence of slurry properties includes coarse sand and sawdust, slurry concentration and viscosity, organic matter in slurry, pH value of slurry, carbonaceous ore;

3.2.3 Influence of Operating Parameters

The operating parameters include aeration volume, aeration mode, sodium cyanide concentration, and carbon retention in the process and so on.

3.3 Test and Control

In the production process, Test worker is necessary to test the slurry concentration, pH value, cyanide concentration, carbon concentration in the slurry, these parameters should be tested once every two hours . In the factory with high degree of automation, on-line monitoring and automatic adjustment of slurry concentration, pH and cyanide concentration are available. The operators need to check the air flow, carbon segregation screen, tank surface all the time.

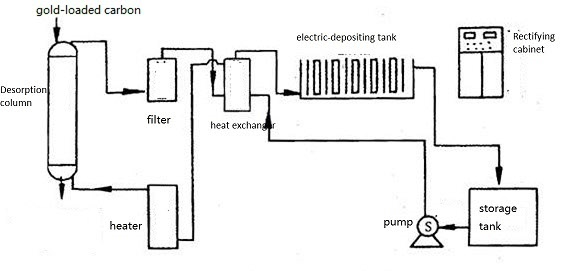

4. Desorption of Gold-loaded Carbon and Electro-deposition

Gold-loaded carbon and slurry are lifted by carbon pump or air-lifter to separation sieve (the most popular sieve is liner vibrating sieve). Gold-loaded carbon and slurry are separated by water on the sieve surface, and then gold-loaded carbon is sent to carbon storage tank and the slurry and water flow into the first absorption tank.

There are several desorption methods. In China, the general application methods are Zadra desorption method, high temperature and high pressure desorption method (hereinafter referred to as HTHP method) and integral pressure desorption method (hereinafter referred to as IP method).

4.1 Zadra Desorption Method

In this way,the desorption solution is composed of 1% sodium hydroxide and 0.1% sodium cyanide aqueous solution. The desorption time is 24-72h at atmospheric pressure of 85-95 C. This method is simple, the investment and production cost is low, but the time is long and the working environment is poor

4.2 HTHP Method

The desorption solution of HTHP method is 0.1% sodium cyanide and 1% sodium hydroxide aqueous solution. The required temperature is 150-170℃, and the pressure is 0.35MPa, the desorption time is only 4-6h, the process conditions can be achieved. This method has advantages of lower consumption of chemicals, fast desorption speed, and short cycle of carbon cycle. But in this method, the pregnant solution need to be cooled before discharging to prevent boiling and splashing;

4.3 IP Method

IP method is similar to HTHP method, but the electro-deposition is located in the pressure system, not need to worry about boiling and splashing, and pregnant solution does not to be cooled before electro-deposition, and the desorption solution was only 5% sodium hydroxide solution. The required temperature is 150℃, and the pressure is 0.5MPa, the desorption time is about 6h, electro-deposition voltage is 2.5-3.0V, and electro-deposition current is 250A. This method is most widely used.

5. Regeneration of the Activated Carbon

After desorption, the activated carbon need regeneration to recover its good adsorption performance.

The regeneration of the activated carbon includes acid-washing and thermal regeneration. Acid-washing regeneration is to soak the activated carbon in 5% dilute nitric acid solution. According to the production practice at home and abroad, acid-washing regeneration can only remove a part of Inorganic substance on the activated carbon, recover the iodine value and carbon tetrachloride of the activated carbon, as well as decrease the ash content of activated carbon. The adsorption capacity and adsorption rate of carbon are not completely improved. After several times acid-washing regeneration, thermal regeneration is needed.

The thermal regeneration process includes four steps: drying, carbonization, carbonization and cooling. After thermal regeneration, the adsorption capacity and adsorption rate of carbon will be fully recovered, and the adsorption activity could be close to or reached the new carbon level.

6. Main equipment in CIL Plant

6.1 The Preparation Equipment before Leaching

The preparation equipment before leaching contains crusher, conveyor, vibrating sieve, ball mill, classifier, debris-removal sieve, thickener and slurry pump.

6.2 Equipment for Leaching and Absorption

The equipment for leaching and absorption includes leaching tank, absorption tank, carbon-lift equipment, Carbon segregation screen and safety screen

7. Equipment for Desorption and Electro-deposition

The equipment for conventional Zadra desorption and electro-deposition method includes: Desorption column, electric heater, electric-depositing tank, filter, heat exchanger, corrosion resisting pump.

The equipment for IP method contains:Desorption column, electric heater, electric-depositing tank, filter, corrosion resisting pump.

Contact us:

|

|

Serena Fu |

Kira Zhang |

|

|

serena.fu@hot-mining.com |

kira.zhang@hot-mining.com |

|

Skype |

Serena20140924 |

kira.zhangjing |

|

+86 151 0833 3341 |

+86 152 8105 1932 |