Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

Hematite Separation Process

Process Introduction

The early hematite beneficiation is mainly gravity separation with machines of jigger, centrifugal separator, spiral chute, spiral washer, shaking table can be involved and later floatation separation has been used in the hematite iron ore upgrading with floatation separator and magnetic separator involved. However, these single separation methods can not help to get ideal beneficiation efficiency. In recently decades, combination of magnetic separation and gravity separation, magnetic separation and floatation separation, gravity separation and floatation separation has been adopted to get high grade hematite iron concentrate.

Application

Hematite is main mineral form of iron oxide and main ore mineral of iron.Hematite coexists with magnetite which can be transformed to hematite by oxidation and remain form of hematite forming the illusion of hematite. Hematite separation process is suitable for complex structure hematite such as hematite and impurities with uneven distribution of particle size, ore with large content of fine particle, ore with small amount of magnetite and the gangue minerals containing quartz or kaolin.The beneficiation process includes stage grinding, coarse-fine particle separation, heavy - Magnetic - anionic reverse flotation process.

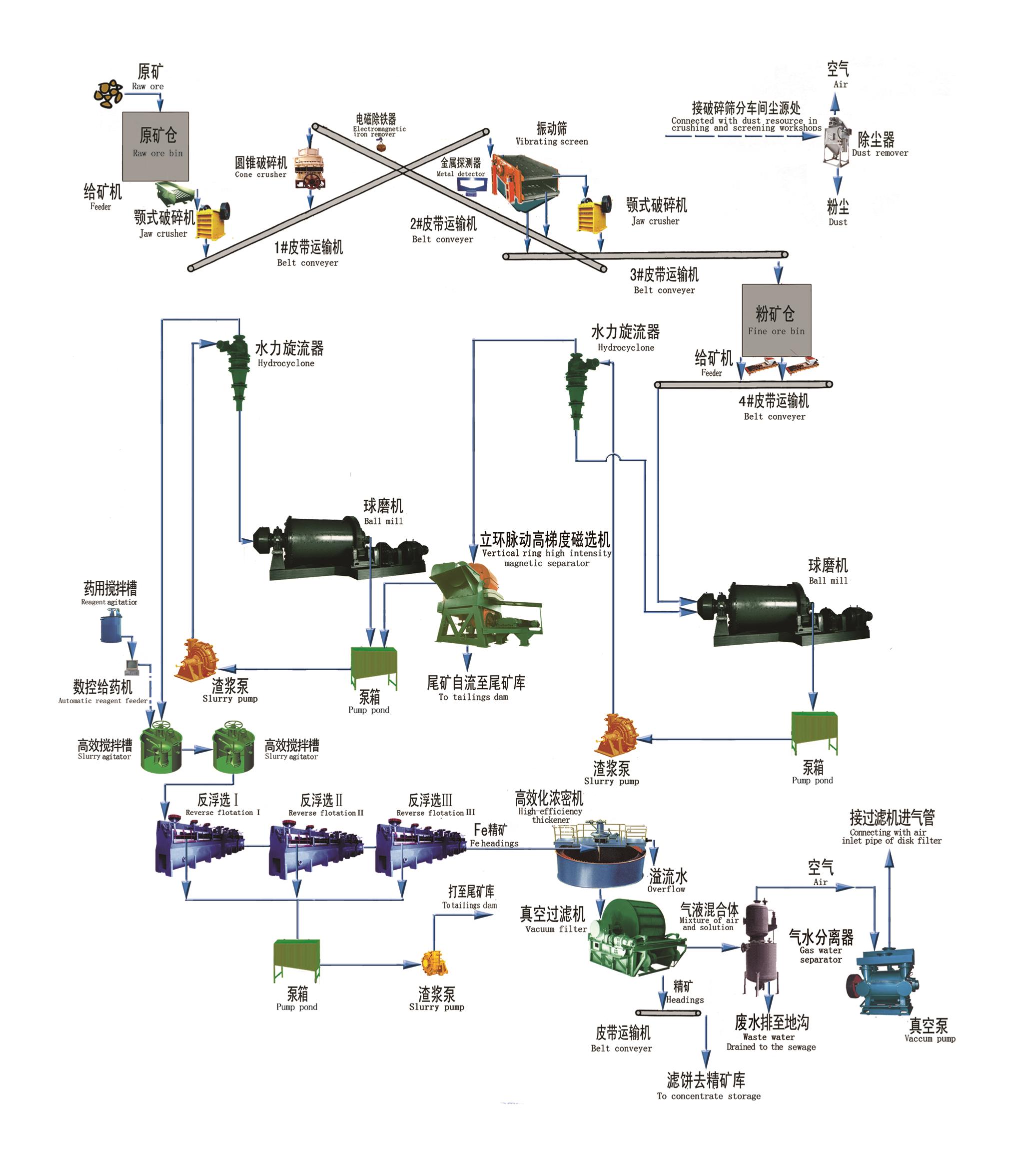

Overall Hematite beneficiation process

1.Hematite ore crushing: in this stage there are also three steps, the hematite ore may go through primary crushing, secondary crushing and fine crushing. Hematite primary crushing equipment includes gyratory crusher, jaw crusher, hammer crusher etc. Hematite secondary and fine crushing plants mainly include cone crusher, ball mill, vertical mill, ultrafine mill etc.

2.Main operation steps in the whole hematite beneficiation process include sorting, gravity separation, floatation, magnetic separation, electrostatic separation, chemical mineral processing etc. There are many plants involves in hematite beneficiation process, such as flotation equipment, magnetic separator, electrostatic separator etc.

3.The treatments of refined hematite mineral include dehydration, tailing disposal, backwater etc. Thickener and dryer are important plants in this stage.

Process Flow for referemce

Quick Detail:

Stage grinding, stage separation and high separation efficiency

The combination of multi process and environmental protection

Strong magnetic separation and reverse flotation process ensure the concentrate grade;

Description:

Stage grinding reduces subsequent operations and costs

Closed circuit grinding consisted of ball mill and cyclone is adopted in the first grinding. This ensures the separation efficiency, particle size and part of qualified concentrate, and it also abandons part of low grade tailings which reduce the grinding volume of medium ore and the loss of metal.

Combined process of magnetic & flotation separation, environment protection

Magnetic separation sorts out the coarse concentrate and tailings, and reduces the working of flotation operation.

Strong magnetic separation and reverse flotation technology, float little and inhibit much, more cost saving

Strong magnetic process recycles fine iron minerals, which can play a dual role of de-sliming and tailings out creating good conditions for flotation. Reverse flotation process system is simple, which can significantly reduce the flotation reagents into pulp and decrease the adverse effect on the flotation process.

Contact us:

|

|

Serena Fu |

Kira Zhang |

Teresa Zheng |

|

|

serena.fu@hot-mining.com |

kira.zhang@hot-mining.com |

teresa.zheng@hot-mining.com |

|

Skype |

Serena20140924 |

kira.zhangjing |

teresa.zheng123 |

Please feel free to give your inquiry in the form below.We will reply you in 24 hours.