Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

The Development of Copper Ore Processing Technology

Copper is one of the earliest discovered and used metals. Because of its good ductility, thermal conductivity, electrical conductivity and corrosion resistance, the consumption of copper is only less than that of steel and aluminum in metal materials consumption, and it has become an indispensable basic material and strategic resource in national economy and people's lives, national defense engineering and even high-tech fields.

Copper is one of the earliest discovered and used metals. Because of its good ductility, thermal conductivity, electrical conductivity and corrosion resistance, the consumption of copper is only less than that of steel and aluminum in metal materials consumption, and it has become an indispensable basic material and strategic resource in national economy and people's lives, national defense engineering and even high-tech fields.

1.Distribution and Occurrence Characteristics of Copper Minerals

There are more than 200 kinds of copper minerals in total, and there are about 15 kinds of common copper minerals in nature, including native copper, chalcocite, covellite, bornite, chalcopyrite, tetrahedrite, tennantite, zigueline, tenorite, chessylite, malachite, chrysocolla, chalcanthitum, brochantite, atacamite. Among the copper ores with industrial value, 80% of them are sulfides, in which most are chalcocite, chalcopyrite, bornite, tennantite, chessylite, and the others are native copper and copper oxide. The copper ore deposits in China are mainly divided into the following categories:

1) Porphyry Copper Deposits: The main minerals are chalcocite and chalcopyrite, with copper grade of 1.0-1.5%, and associated minerals are pyrite, sphalerite, molybdenite, copper-nickel ore and gold.

2) Layered Copper Deposits: the main minerals are chalcopyrite, bornite, chalcocite, malachite, chessylite, chrysocolla, and rare tetrahedrite.

3) Pyrite-type Copper Deposits: pyrite is the main ore, accounting for more than 95% of the total, including chalcopyrite and sphalerite.

4) Skarn-type Copper Deposits: They are mainly composed of gossan, malachite and chalcopyrite. There are often secondary enrichment zones in the lower part of skarn-type copper deposits, which are composed of dense and fume-like chalcopyrite.

5) Vein Copper Deposit: The main minerals are chalcopyrite, pyrite, sphalerite, galena, tetrahedrite, pyrrhotite, porphyry, chalcopyrite, etc.

6) In addition, there are sandstone-type copper deposits, copper-nickel sulfide deposits and andesite basalt copper deposits.

Porphyry copper deposits account for more than 60% of the total reserves of all types of copper deposits in the world, sandstone copper deposits account for about 25%, copper-bearing pyrite for more than 5%, and other types of copper deposits account for less than 10%.

From the proved copper reserves, although China's copper reserves rank 7th in the world, but the per capita possession is low, and the number of high-grade ore available is relatively small, while China's copper resources demand is huge.

Therefore, improving the processing and metallurgical technology of copper resources is the unremitting pursuit of many scientific researchers and production technicians.

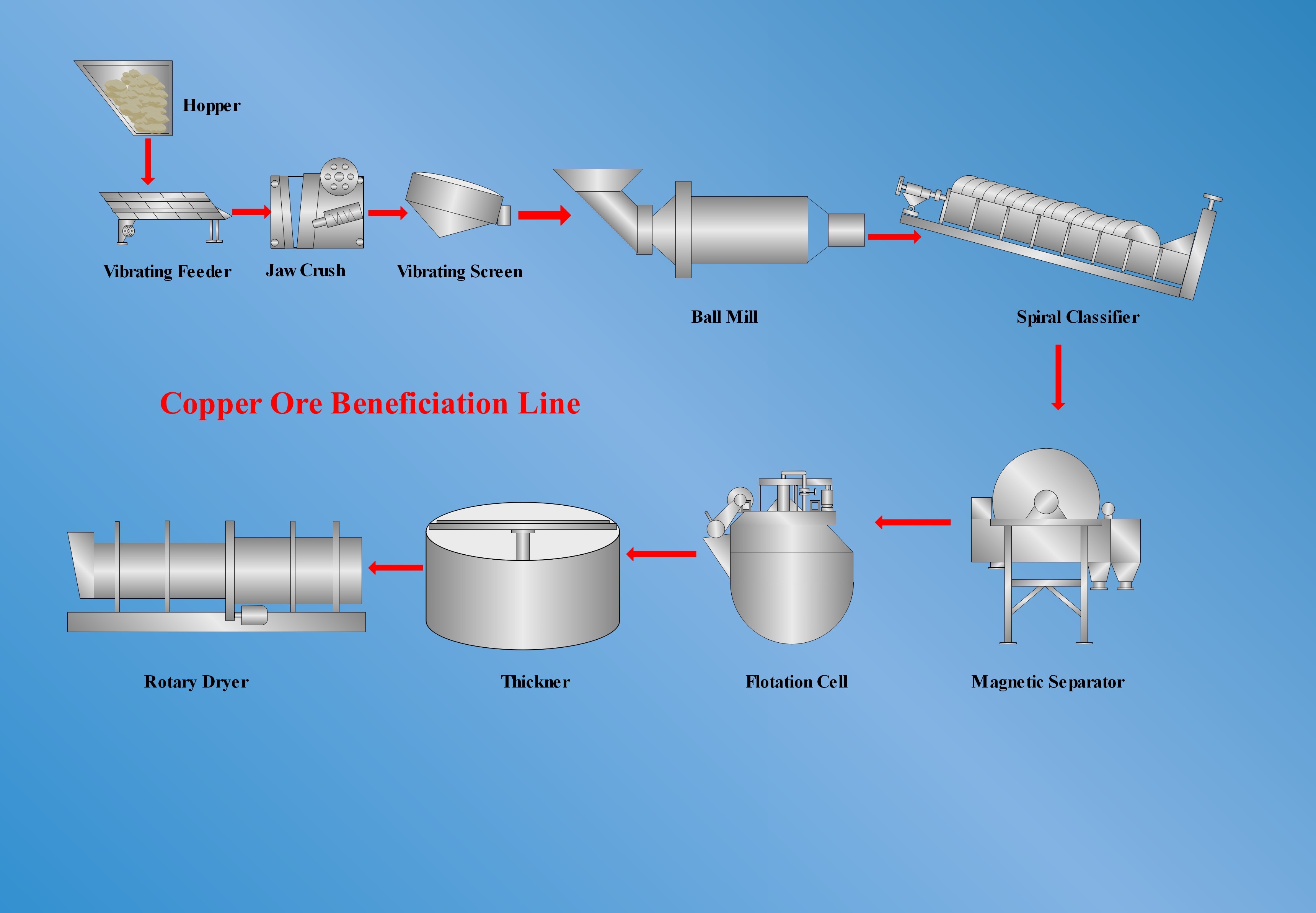

2.Processing Technology of Copper Ore

"Low grade, many impurities, high oxidation rate, and difficult to separate" are the most appropriate descriptions of China's copper resources. It’s estimated that more than 40% of China's copper resources are hard to utilize. Therefore, how to develop and utilize refractory copper ores has become an important topic in copper processing research. Copper ores suitable for processing mostly occur in various types of deposits. The types of deposits with mining value in China include magmatic copper-nickel sulfide deposits, porphyry copper deposits, sedimentary layered deposits and so on, with relatively low grade. The structure of the ores is complex and the size of the ore is inhomogeneous, and most of them are non-uniformly disseminated. There are even many mineral assemblages with fine structure, complex composition and more refractory ores. The mineral composition is diverse, accompanied and symbiotic with many beneficial and harmful components, and the processing conditions are complex. At present, most of the copper deposits developed in China are comprehensive, accompanied by a variety of beneficial and harmful elements. How to make comprehensive use of these resources and turn harm into benefit is also the main objective of the study of processing.

Generally, different processing methods are adopted for different ore types:

Ø flotation method is commonly used for single sulfide ore;

Ø For polymetallic sulfide ores, different separation methods are adopted for different composition characteristics, including mixed flotation, preferential flotation, mixed preferential flotation, combined flotation and gravity method, combined flotation and magnetic method, combined flotation and hydrometallurgy method, etc.

Ø Copper ore with high combined oxidation rate is usually treated by hydrometallurgical method.

Ø Mixed ores can be treated by flotation alone or be treated by flotation with sulfide ores, or combined flotation and hydrometallurgy, i.e. copper concentrate is obtained by flotation firstly, and then tailing after flotation is treated by hydrometallurgy.

2.1 Flotation

The flotation process for copper sulfur ores varies widely. Generally speaking, it can be divided into priority flotation, mixed flotation, iso-floatability flotation, partial priority flotation ~ mixed flotation, fast flotation, distributed priority flotation, partial mixed flotation and asynchronously mixed flotation. The development of newly processing technology is mainly based on the principle of "quick recovery, early recovery and early discharging of waste". It can be shown in the following aspects: more crushing and less grinding, asynchronous flotation, branch-stream flotation, electrochemical controlled flotation and primary potential controlled flotation.

The flotation of copper oxide ore includes direct flotation and indirect flotation. Direct flotation is mainly used to treat copper oxide ores with simple mineral composition and uncomplicated properties; indirect flotation is to sulfide copper oxide ores by adding sulphide agent, and then flotation with common sulphide flotation agent. This method requires high sulphidation effect, and it will directly affects the flotation effect of sulphide ores.

In addition to optimizing the flotation process of copper ores, a lot of work has been done on the agents, mainly for the study of foaming agents and collectors. The research focuses on reducing toxicity and improving effect. At the same time, a lot of efforts have been made in agents mixing and pre-treatment technology, which has greatly reduced the dosage and cost of agents and greatly improved environmental pollution.

2.2 Hydrometallurgical Process for Copper

Since the introduction of hydrometallurgical process for copper in the late 1980s, it has been widely used in China, especially for copper-bearing materials that cannot be effectively recovered by conventional processing methods, such as waste rock from open-pit ore stripping and low-grade copper oxide ore. Hydrometallurgical process is the process of extracting copper from pregnant liquid by leaching copper from ore or concentrate with solvent. The main processes include leaching, solvent extraction, electrodeposition and so on.

At present, leaching methods mainly include heap leaching, underground leaching, stirring leaching and biological leaching.

Ø Heap leaching is widely used to treat unclassified or crushed copper-bearing waste, tailing and lean ores.

Ø Leaching is carried out in a leachate or pond. It is suitable for treating concentrates or ores with high grade and particle size less than 5mm.

Ø Stirring leaching is usually used to treat high grade ore or concentrate, copper recovery is high and leaching speed is fast.

Ø Leaching~solvent extraction~electrowinning method can not only obtain high quality cathode copper from ore in mine site, but also lower initial investment and production cost than conventional flotation and pyrometallurgy.

-

Leaching is widely used in North and South America, and it is also widely used in China. Ores treated by this process generally need to satisfy the following conditions:

1) The main copper mineral in the ore is the chalcopyrite which is easy to leach.

2) The recovery of by-products such as gold, silver and molybdenum can be ignored.

3) The acid consumption of gangue minerals should not be too much.

4) Heap leaching is not suitable for places with low temperature, often rain and high-altitude climate and geological conditions.

5) The site should can make full use of the existing equipment to reduce new investment;

The main advantages of this method include: can treat low grade copper ore, especially suitable for treating lean ore, waste ore, surface ore and refractory ores. It has the outstanding advantages of simple process, low cost, low energy consumption and low environmental pollution. In the United States, this method has been used to treat ultra-low grade copper ores with less than 0.04% and has been successful.

The hydrometallurgical process has been put into production and application in Zijin Copper Mine, Zhongtiaoshan Copper Mine and Dexing Copper Mine in China, and satisfactory results have been achieved.

At present, the research of hydrometallurgical process in China is mainly about the speed and rate of copper leaching.

A research team led by Professor Qiu Guanzhou of Central South University carried out the research on the composite catalyst of low-grade copper and zinc ore and the new technology of bioleaching of improved bacteria. The key technology of this study is to use mutagenic strains and composite catalysts to enhance both direct and indirect processes in order to improve the leaching rate and leaching rate.

For the first time, the researchers used pyrrhotite to screen dominant bacteria in leaching, ultraviolet-nitrite mutagenesis, domestication, adaptive culture and other breeding methods and means to breed six kinds of high-efficiency and excellent leaching strains with strong adsorption, high oxidation activity and strong tolerance from Thiobacillus ferrooxidans. It has also been applied to the bioleaching of low-grade chalcopyrite-type primary copper sulfide ore, and the leaching speed and leaching rate have been significantly improved. The technology has been widely applied in copper mine projects in Jiangxi and Yunnan provinces with remarkable economic benefits.

3.Development Direction of Copper Ore Processing Technology

The development of copper ore processing technology cannot be separated from the support of equipment. Because the grade of copper ore is lower than that of iron ore and the processing capacity of copper ore is larger, large-scale, energy-saving and high-efficiency processing equipment is a way to improve the grade of copper concentrate and economic benefit of copper mine. At present, remarkable achievements have been made in the application of large-scale flotation machine, AG mill/SAG mill and flotation column.

In the recovery and utilization of refractory copper oxide ores, it will be a major trend for the development of processing technology of refractory copper oxide to seek efficient flotation reagents or combination reagents.

In addition, in terms of process improvement, the current research mainly focuses on the research of fast flotation, early removal of waste, reduction of overgrinding and undergrinding, etc. At the same time, the joint process is also the focus of current research.

At present, the proportion of copper recovery by bioleaching accounts for about 25% of the world's total copper production. There’re only two copper mines in China adopt this method, so it is still a long way to go to develop the bioleaching process in China. For some refractory copper oxide ores which are difficult to be processed by flotation, chemical mineral processing method plays an important role, especially the leaching-extraction-electrowinning process with the advantages of low unit cost, less environmental pollution and strong adaptability, which is bound to be one of the main directions of technical development of refractory copper oxide mines at present and in the future.

Contact us: