Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

Application of MES Process® Series Color Sorter in Barite

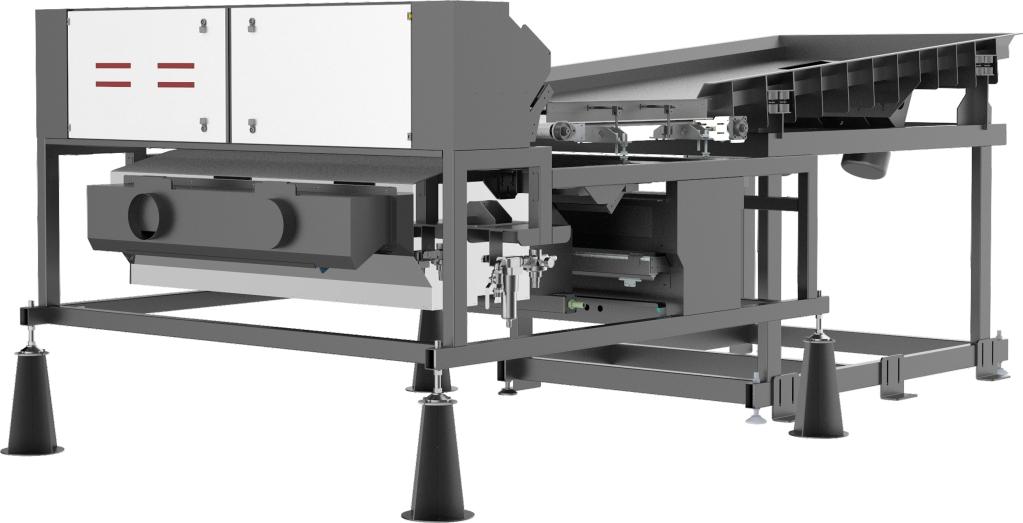

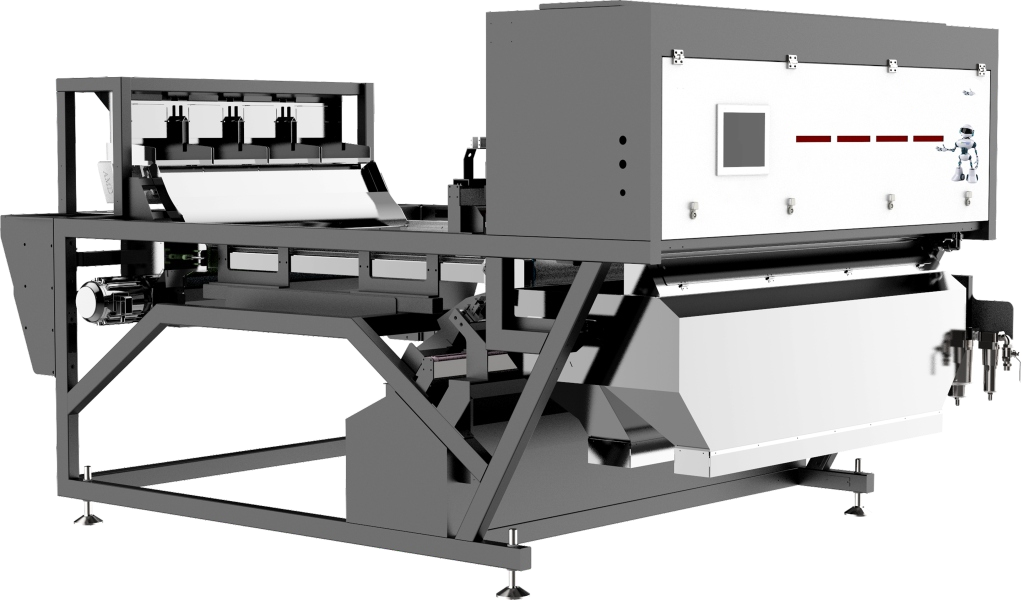

1. Introduction to MES Process® Ore Color Sorter

In the mining sorting industry, the ore color sorter is also called sensor-based sorting technology. Optical color sorters (CCD color camera) combine X-ray sorting technology and NIR (near infrared spectrometry) to pick out the impurities of ore, minerals, stone and sand products, or separate ore into two or more categories.The ore raw materials containing some valuable minerals mined from the mine can be used in engineering fields such as construction industry, cement industry and gravel industry after step-by-step processing such as crushing, grading, color separation and grinding. Among them, the preparation of ore is particularly important. After color sorting, the ore has high purity and uniform color, which greatly improves the utilization rate of ore and doubles its value.

2. Working Principle of Ore Color Sorter

MES Process® Ore Color Sorter developed by HOT Mining separates selected materials according to different colors through high-resolution sensors based on the difference of optical characteristics of materials and the principle of photoelectric detection, so as to realize automatic sorting. There are light source, high-speed camera and air jet nozzle above the material. The air jet nozzle sprays high-pressure air to change the running track of the material, so as to realize the entry of good and bad materials into different receiving areas. At present, it has been successfully applied to the beneficiation and purification of non-metallic minerals such as quartz, feldspar and fluorite.

Working Principle of MES Process® Ore Color Sorter

3. Advantages of MES Process® Ore Color Sorter developed by HOT Mining

·Double layer sort, high sorting accuracy·Support dry or wet separation to realize continuous production

·Remote control

·Customized algorithm, bring out ratio is smaller

·The real-time display of physical image can separate a variety of ores of different sizes

·Low consumption, high frequency solenoid valve, with anti dust environment

4.Several factors affecting the effect of ore color sorter

·Differentiation of raw materials: different raw materials have different requirements for application. Therefore, when using the ore color separator, we must not only pursue the output of raw materials, but also consider the original material and select different color separation applications for different materials, so that the effect of color separation can be optimized.·Flexible adjustment of performance indicators: debug different performance indicators according to the requirements of color selection. When the color selection effect can meet the requirements, the lower the sensitivity, the better. Excessively improving the sensitivity will cause the solenoid valve to blow too much and enter the protection state, which may worsen the color selection effect.

·Impurity content of raw materials: when there are few impurities, the interval between the two impurities is large, leaving a long reaction time for the system. At this time, the speed of the conveyor belt can be increased and the output can be increased; Similarly, the higher the initial purity of raw materials, the less impurities, the higher the color separation accuracy, the less impurities and the better the effect.

·Shading of color difference: the color sorter mainly selects materials according to the color difference of materials. Generally, there must be a certain color difference between normal materials and defective materials in raw materials. The smaller the color difference is, the more difficult the color selection is, the worse the performance index is, and the selection rate of materials with different colors is also different.

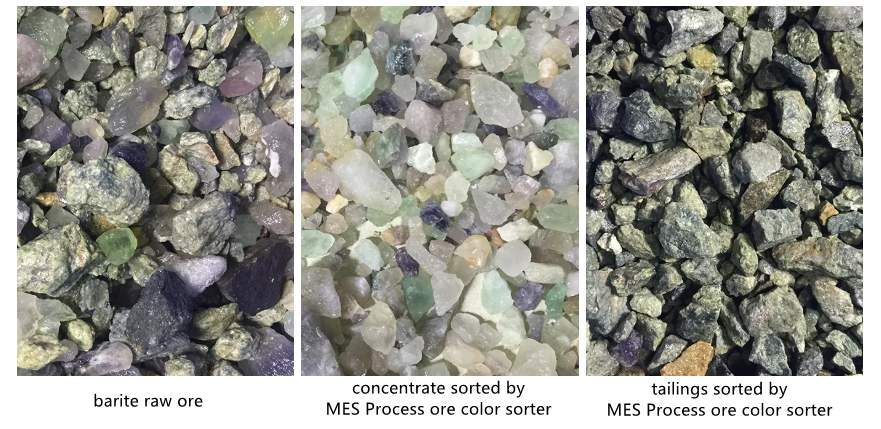

5. Barite Color Sorting

Barite is the most common mineral of barium, and its component is barium sulfate. At present, barite is widely used in many industries. With the economic development and social progress, the requirements for barite are becoming more and more stringent. Therefore, the sorting of barite is indispensable.

As a new automatic ore separation equipment, MES Process® Ore Color Sorter separates minerals through color. At present, it is also used for the separation of barite, and has achieved better results than the original purification method. The figure below shows the effect of barite sorted by MES Process® Ore Color Sorter.

Effect of barite sorted by ore color sorter

In short, the MES Process® Ore Color Sorter developed by HOT Mining is very important for the development of barite in China. It can not only solve the dilemma of domestic barite development, but also open up a new chapter of its rapid development. Reduce the cost of imported barite ore, reduce the pressure on domestic mining industry, and seek development based on technology.