Company:China Mineral Processing & Metallurgy League

Email: sales@hot-mining.com

Phone:+86 18252116933

Fax:+86 10 58646590

Address:Room10811, Floor8, Building A, Galaxy SOHO, Dongcheng Dist, Beijing, P.R.China

Antimony Mineral Processing

Process Introduction

Proportion of antimony ore is far greater than proportion of gangue, so it will be separated by using the method gravity separation. This method has many features, high efficiency, energy saving, and environment protection, which can make the low-grade ore enrichment advance. After gravity separation, the antimony will be purified by floatation. So the processing method of HOT mining is gravity separation-flotation process.

Application

HOT mining’s gravity separation-flotation process is applied to all kinds of antimony ore.

Process Description

HOT mining 's gravity separation-flotation process

The ore after hand sorting will go through coarse crushing and fine crushing, during which the size of mineral should be under 30mm, and screening classification have three size fractions, 8-30mm, 2-8mm, 0-2mm. then the three kind of minerals will go respectively into Jig, and HOT mining Sawtooth Wave Jig to gravity separation. The mixted concentrate from the last stage will be go into the gravity concentrate district. Then after the process of gravity, there will be a process of floatation, the tailings from the preview gravity separation will be grinded, separated, stirred,and floated. And the floatation will apply the process of roughing, three cleanings, and two scavenging;. Then high grade antimony fine powder will be produced. The tailings from the floatation will be reelected by shaking table to recycle the fine antimony particles, which we can get high grade antimony concentrate and tailings.

Case

In one of HOT mining 's project, antimony content is 3.09%, among which the share of antimony sulfide is about 94.78%, and a small amount of antimony is existed in valentinite or antimonite, about 4.82%. Carbon content of the ore is 6.54%, in which the inorganic carbon have up to 5.53%, and is antimony sulfide with high-carbon and very complex for dressing. After multi scheme of test, HOT mining finally decided to use gravity separation-flotation process to recycle the antimony ore, and in the test the grade of antimony is 59.21%, the recovery rate of mixed antimony concentrate Is 94.13%. HOT mining achieved the maximum intensity of the recovery of the antimony ore, which reduced the environmental pollution caused by tailings and also gained excellent economic benefit.

Related Products

|

|

|

|

| Jaw Crusher | Energy Saving Ball Mill | Air Inflation Flotation Cell | Jig |

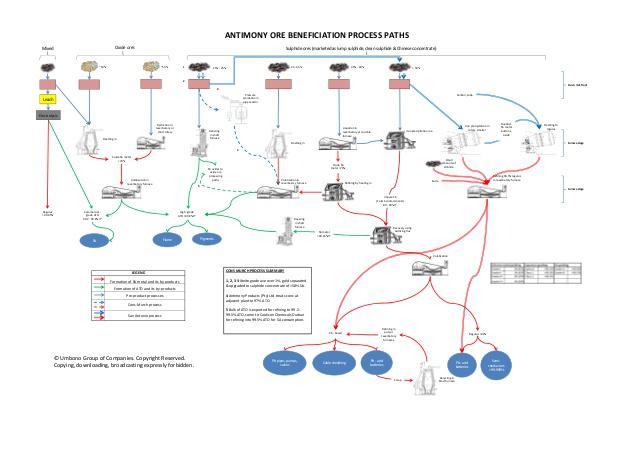

Process Flow

Contact us:

|

|

Serena Fu |

Kira Zhang |

Teresa Zheng |

|

|

serena.fu@hot-mining.com |

kira.zhang@hot-mining.com |

teresa.zheng@hot-mining.com |

|

Skype |

Serena20140924 |

kira.zhangjing |

teresa.zheng123 |